Reconditioned drums can be either plastic or steel drums that have undergone the reconditioning process to ensure optimum repeat use. Whereas in drum reconditioning, the drum is not often altered with new materials or parts (except for the lid), remanufactured drums must undergo a much more intense process, changing many aspects of the old drum. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

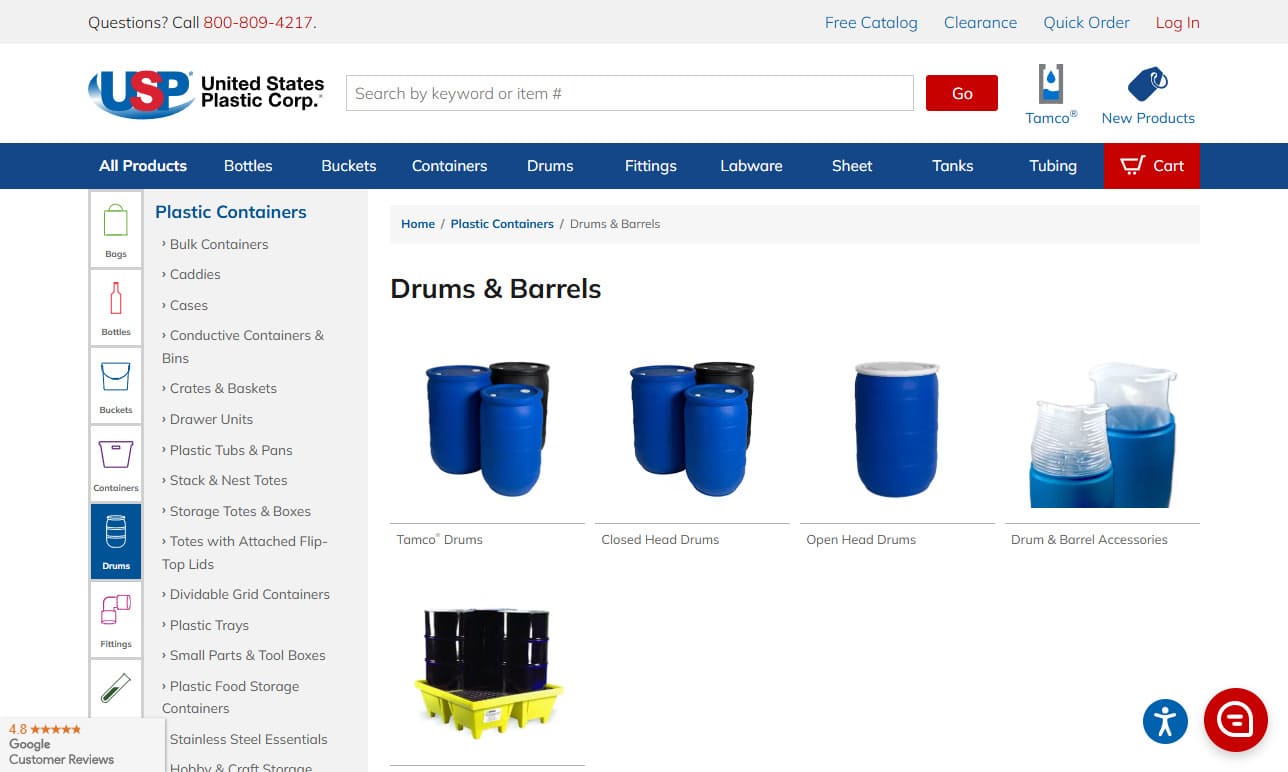

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Used Drum Manufacturers

Used Drums: Cost-Effective, Sustainable Solutions for Industrial Storage and Transport

In today's competitive industrial landscape, businesses are increasingly seeking cost-effective and sustainable solutions for material storage and transportation. Used drums—including reconditioned and remanufactured steel, plastic, and fiber drums—offer a practical alternative to newly manufactured drums across a wide range of sectors. Their affordability, environmental benefits, and compliance with international quality standards make them a preferred choice for companies focused on operational efficiency and eco-friendly practices.

What Are Used Drums?

Used drums are industrial containers that have previously served in the storage or transport of goods, including chemicals, oils, food products, pharmaceuticals, and hazardous materials. After initial use, these drums are inspected, cleaned, and restored through reconditioning or remanufacturing processes to ensure they meet rigorous safety and performance standards. The most common types include:

- Reconditioned steel drums

- Reconditioned plastic drums

- Remanufactured fiber drums

- IBC totes (Intermediate Bulk Containers)

- Salvage drums for hazardous materials

These used containers are available in various sizes, including 30-gallon, 55-gallon, and 205-liter capacities, tailored for specific industrial applications. If you're searching for "where to buy used drums near me" or "used 55-gallon drums for sale," this guide will help you understand the key factors that influence your buying decision and how used drums can benefit your operations.

Industries That Rely on Used Drums

Many industries across the globe utilize used drums as an integral part of their supply chain, storage, and logistics operations. Here are some of the most prominent sectors and their use cases:

- Industrial manufacturing: Used drums are essential for the storage and transport of a variety of chemicals, lubricants, solvents, and raw materials required in machinery and production processes.

- Automotive and aerospace: These industries rely on reconditioned drums for safe handling and storage of oils, greases, coolants, and other maintenance chemicals vital for vehicles and aircraft.

- Medical and pharmaceutical: Used drums are employed for secure containment and transportation of potentially hazardous waste, medical ingredients, and pharmaceutical chemicals, following strict regulatory protocols.

- Food and beverage: Food-grade used drums enable sanitary storage and handling of liquids, syrups, and food ingredients of various viscosities, ensuring compliance with food safety standards.

- Agriculture and farming: Farmers and agricultural suppliers utilize used drums for bulk storage of fertilizers, pesticides, animal feed, and water.

- Waste management and environmental services: Used drums are repurposed for the containment, transport, and disposal of hazardous and non-hazardous waste materials, supporting environmental sustainability.

Whether you are a facility manager, procurement specialist, or operations supervisor, understanding how used drums can fit into your specific workflow is crucial. Are you wondering which type of used drum is right for your industry? Explore our industry applications section below for detailed use cases.

Quality Standards and Compliance: Ensuring Safety in Used Drum Applications

Despite their prior use, used drums must adhere to stringent material handling and safety standards. Regulatory organizations such as the United Nations (UN) and the International Organization for Standardization (ISO) set forth comprehensive guidelines for the inspection, testing, and certification of reconditioned and remanufactured drums. This ensures that businesses can safely reuse drums without compromising product integrity or workplace safety.

Key compliance factors include:

- Leak prevention: All used drums must pass detailed leak testing to confirm that they provide a secure seal for both hazardous and non-hazardous contents.

- Integrity and durability: Drums are inspected for dents, corrosion, and structural weaknesses. Only those that meet or exceed operational standards are approved for re-use.

- Closure mechanisms: All gaskets, lids, and closure systems are thoroughly checked and, if necessary, replaced or upgraded during the reconditioning process.

- Certification markings: Approved drums are clearly marked with updated compliance labels as required by UN, ISO, and Department of Transportation (DOT) regulations.

Looking for more information on used drum regulations or how to ensure compliance in your supply chain? Check out our Frequently Asked Questions section or contact our compliance experts for guidance.

Reconditioning vs. Remanufacturing: Understanding the Differences

When considering used drums for your facility, it’s essential to understand the distinctions between reconditioning and remanufacturing, as each process impacts the drum’s suitability for different applications.

Reconditioning Process

Reconditioning involves restoring a used drum to a condition suitable for repeated use. The process typically consists of the following steps:

- Leak testing: A visual and technical inspection ensures the drum is leak-proof and structurally sound.

- Dent removal: Dents and deformations are corrected to restore the drum’s original shape and capacity.

- Coating removal: Any previous interior or exterior coatings are stripped away using chemical or mechanical methods, preparing the surface for new coatings or direct use.

- Closure system inspection: All lids, gaskets, and closure components are examined and, if necessary, replaced to guarantee a secure seal.

- Repainting and marking: The drum is repainted for corrosion resistance and marked for traceability and compliance.

- Chime straightening (for steel drums): The drum’s chime, or rim, is straightened to improve stacking and sealing performance.

Reconditioned drums are ideal for companies seeking affordable, ready-to-use containers for non-critical or non-food applications. They are often available at a fraction of the cost of new drums, making them a popular choice for budget-conscious operations and sustainable procurement strategies.

Remanufacturing Process

Remanufacturing is a more intensive process that involves structural modifications or upgrades to extend the drum’s service life and enable use in more demanding applications. The four primary types of drum remanufacturing include:

- UN 1A1 to UN 1A2 conversion: Modifying a closed-head (tight head) drum to an open-head (removable lid) configuration for versatility in filling and emptying.

- Structural component replacement: Replacing integral parts of the drum, such as rolling hoops, to restore or enhance performance.

- New rolling hoop manufacturing: Fabricating and installing additional rolling hoops to reinforce the drum’s structure and stacking capabilities.

- Specification conversion: Altering a drum to meet a new set of regulatory or industry specifications, broadening its application range.

Remanufactured drums are well-suited for critical operations that demand higher structural integrity, stringent regulatory compliance, or specialized features. Businesses in chemical processing, hazardous waste management, and bulk liquid transport often opt for remanufactured drums to ensure maximum safety and reliability.

Key Applications and Use Cases for Used Drums

Used drums are remarkably versatile, serving diverse applications across commercial, industrial, and even residential settings. Some of the most common use cases include:

- Chemical storage and transport: Safely contain and move solvents, acids, bases, and specialty chemicals.

- Bulk food ingredient storage: Store syrups, edible oils, grains, and flavorings in food-grade reconditioned drums.

- Hazardous material management: Comply with EPA and DOT regulations for storing and transporting hazardous waste or chemicals.

- Rainwater harvesting: Repurpose used drums for collecting and storing rainwater in agricultural and eco-friendly home applications.

- Emergency preparedness and spill containment: Utilize salvage drums for spill response and emergency storage of dangerous materials.

- Industrial waste disposal: Rely on certified used drums for safe containment and transport of industrial byproducts.

- DIY and creative projects: Used drums can be upcycled into furniture, compost bins, barbecue grills, or planters for creative reuse.

Have a specific storage or transport challenge? Ask us which type of used drum is best for your application or browse our in-depth FAQ section for answers to common questions about drum selection and usage.

Benefits of Choosing Used Drums Over New Drums

Opting for used drums offers a range of advantages for businesses and individuals alike. Here are some of the most compelling benefits:

- Cost savings: Used drums can cost 30-70% less than new drums, providing immediate savings on procurement without sacrificing quality or safety.

- Environmental sustainability: By reusing drums, you reduce landfill waste, lower your carbon footprint, and support a circular economy. Many companies highlight their use of reconditioned containers in sustainability reports.

- Regulatory compliance: Properly reconditioned and remanufactured drums meet or exceed industry regulations, allowing you to safely store and transport sensitive materials.

- Quick availability: Used drums are often readily available for immediate delivery, minimizing supply chain delays and supporting just-in-time inventory strategies.

- Variety and customization: Access a wide range of sizes, materials, and closure options to fit your exact requirements. Many suppliers offer custom painting, labeling, or linings for specialized needs.

- Supports green branding: Demonstrate your commitment to environmental responsibility by using recycled and sustainable packaging solutions.

Curious about the environmental impact of your drum choices? Explore our resources on sustainable packaging to learn how used drums contribute to your organization’s green initiatives.

Factors to Consider When Buying Used Drums

When sourcing used drums for your operations, it’s important to evaluate several key decision factors to ensure optimal performance and safety. Here’s a checklist to guide your selection process:

- Material compatibility: Confirm that the drum’s material (steel, plastic, or fiber) is suitable for the intended contents and application.

- Regulatory requirements: Check for required certifications, such as UN/DOT approval for hazardous material transport.

- Previous contents: Verify the drum’s prior use to avoid cross-contamination, especially for food-grade or pharmaceutical applications.

- Condition and appearance: Inspect for visible damage, corrosion, or residue. Ask for inspection reports or photos from the supplier if buying online.

- Supplier reputation: Choose a reputable supplier with a track record of quality, compliance, and customer support.

- Volume and logistics: Consider your storage space, delivery requirements, and minimum order quantities.

- Customization or refurbishing needs: Determine whether you need special coatings, linings, fittings, or labeling.

Need help selecting the right used drum? Contact our sales team for personalized recommendations, or use our Drum Selection Guide for step-by-step assistance.

Frequently Asked Questions About Used Drums

Where can I buy used drums?

Used drums can be purchased from specialized industrial suppliers, drum reconditioning facilities, online marketplaces, and local distributors. When searching for “used drums for sale near me,” be sure to compare prices, certifications, and shipping options. Many suppliers offer nationwide delivery and bulk discounts.

Are used drums safe for food products?

Yes, provided they are food-grade reconditioned drums that have never contained hazardous materials. Always verify previous contents and request certification of food-grade status.

What is the difference between a reconditioned and a remanufactured drum?

Reconditioned drums are cleaned, tested, and restored for reuse, typically for non-critical or general-purpose applications. Remanufactured drums undergo more extensive structural changes and component replacements, making them suitable for demanding or regulated industries.

How do I ensure regulatory compliance when using used drums?

Always purchase from reputable suppliers who provide documentation of compliance with relevant UN, DOT, and ISO standards. Request copies of inspection reports and compliance certificates as part of your procurement process.

Can I use used drums for hazardous waste or chemicals?

Yes, as long as the drums are UN/DOT certified and specifically approved for hazardous materials. Check the certification markings and verify with the supplier before use.

What are some creative uses for used drums?

Beyond industrial applications, used drums can be transformed into rain barrels, composters, planters, barbecue grills, or even furniture pieces. If you’re interested in upcycling, explore our Creative Uses Guide for inspiration.

How to Source Reliable Used Drum Suppliers

Choosing the right supplier for used drums is critical to ensuring safety, compliance, and consistent quality. Here are some tips for finding reputable vendors:

- Look for industry certifications: Reputable suppliers hold ISO, UN, or DOT certifications and are members of industry associations such as the Reusable Industrial Packaging Association (RIPA).

- Ask for documentation: Request inspection reports, photos, and compliance certificates to verify the quality of used drums.

- Read customer reviews: Check online testimonials and ratings to gauge supplier reliability and service quality.

- Inquire about logistics: Confirm delivery options, lead times, and minimum order quantities to ensure smooth procurement.

- Evaluate customer support: Choose a supplier with responsive sales and technical support teams to assist with selection and after-sales service.

Ready to purchase used drums or have questions about your specific requirements? Contact us today for a quote or a free consultation on bulk drum supply, reconditioning services, and compliance solutions.

Conclusion: Unlock Value and Sustainability with Used Drums

Used drums are a smart, sustainable, and cost-effective choice for a wide variety of industrial and commercial applications. By choosing reconditioned or remanufactured containers, you not only save on procurement costs but also support environmental responsibility and regulatory compliance. Whether you’re seeking used steel drums, plastic barrels, fiber drums, or IBC totes, understanding your options and sourcing from reliable suppliers is key to maximizing value and safety.

If you’re ready to streamline your storage and transport operations or want to learn how used drums can enhance your sustainability initiatives, reach out to our team for expert guidance. Browse our resource library for detailed information on drum selection, compliance, and creative reuse, or request a personalized quote for your next order.

55 Gallon Drums

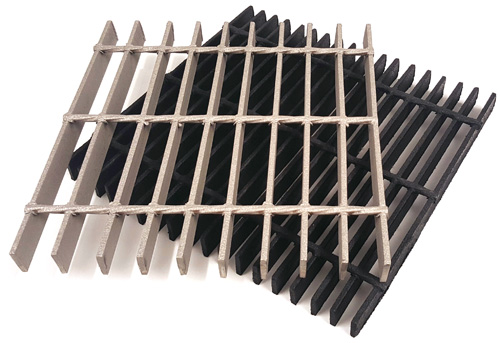

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services