Steel barrels, also known as 55-gallon drums, are commonly used in various industries for their durability, reusability, and cost-effectiveness. From industrial use to food and beverage storage, steel barrels play a vital role in modern society. In this article, we will explore the process of creating steel barrels, discuss their variations, benefits, and highlight their applications in different industries. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

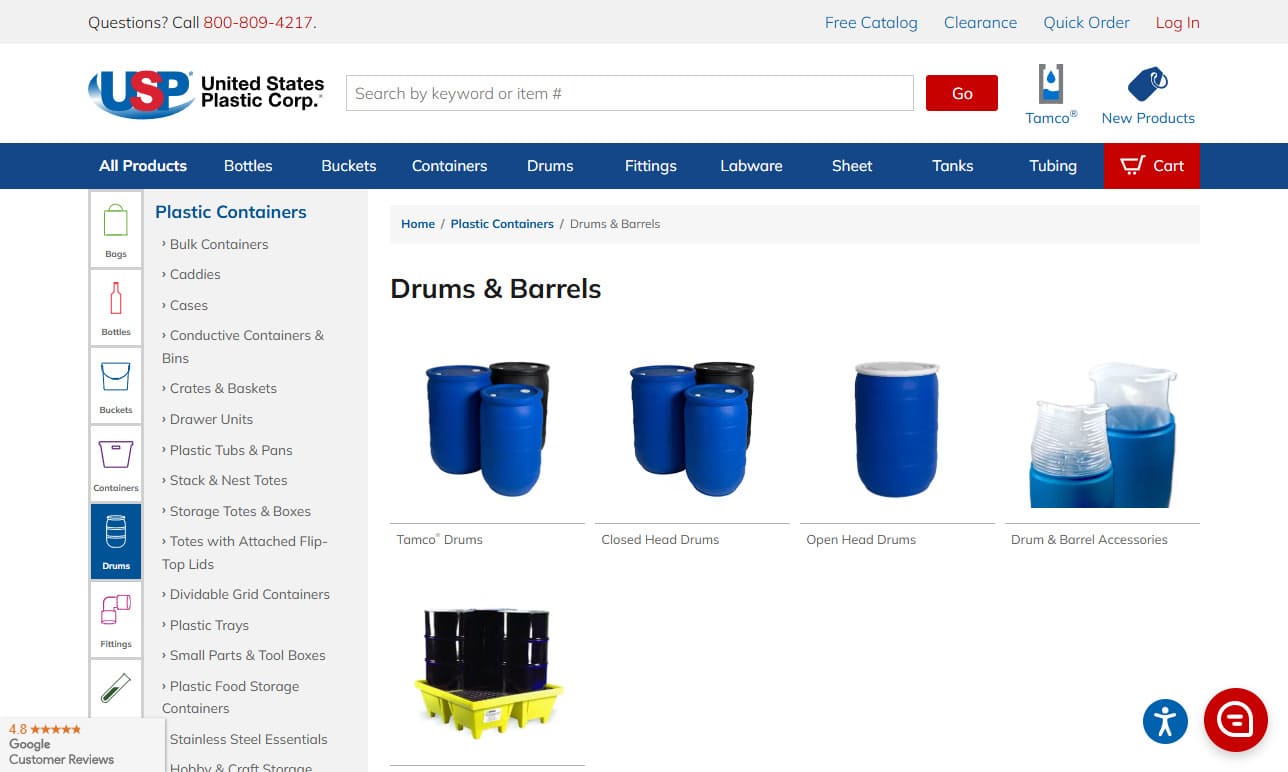

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Steel Barrel Manufacturers

Creating Steel Barrels: Manufacturing Processes and Industry Standards

Steel barrels, also known as steel drums, are essential industrial packaging solutions designed for the safe storage and transportation of a wide variety of liquids, solids, and semi-solids. Their robust construction and versatile design make them a preferred choice for industries such as chemicals, oil and gas, food processing, pharmaceuticals, and hazardous waste management.

The manufacturing of steel barrels typically involves a process known as drum rolling. This process begins with large, flat steel sheets—usually cold-rolled or hot-rolled steel, chosen for its high strength and formability. These steel sheets are cut into precise circular blanks, which are then formed into cylindrical shapes using hydraulic presses and rollers. The ends of the cylinder, known as the chimes, are flanged to increase rigidity and ensure a tight seal.

Next, the two ends of the steel drum are sealed with end caps, commonly referred to as lids or heads. Depending on the drum design, these may be welded or mechanically fastened to the barrel body. A steel locking ring or closure ring is often used to securely hold the head in place (especially on open head barrels), providing both tamper resistance and ease of reuse. The finished steel barrels are then tested for leak resistance, pressure integrity, and compliance with relevant standards such as UN/DOT regulations for hazardous materials packaging.

Curious about how steel barrels are made, or which manufacturing standards are most important for your application? Explore our detailed guide below or contact a steel barrel expert for tailored advice.

Variations of Steel Barrel Designs: Customization and Use Cases

The versatility of steel barrels stems from their range of designs, each engineered to meet specific storage, transportation, and regulatory requirements. The main steel drum types include:

Open Head Steel Barrels (Removable Head Drums)

Open head steel barrels, also known as removable head drums, feature a fully detachable lid that provides wide access to the drum’s contents. This makes them ideal for applications where frequent filling, dispensing, or cleaning is required. The lid is typically secured using a bolt ring or lever lock ring, ensuring a tight closure while still allowing for easy removal.

Common use cases for open head steel drums include the storage and transport of dry goods (such as grains, powders, and bulk materials), chemicals, hazardous waste, and even food products in certain industries. Their design allows for easy integration of custom closures—like bung openings, gaskets, and tamper-evident seals—tailored to the customer's requirements.

- Easy access for filling, dispensing, and cleaning

- Customizable with liners for contamination control

- Ideal for solid materials, powders, and viscous substances

- Available with UN/DOT certification for hazardous materials

Tight Head Steel Barrels (Closed Head Drums)

Tight head steel barrels, also known as closed head drums, feature a permanently sealed top with only two bung openings (typically 2-inch and ¾-inch). These bungs allow for controlled filling and dispensing while maintaining a secure, leak-proof environment. Tight head drums are preferred for liquid storage and transport, especially when complete containment is essential.

Industries such as oil and gas, petrochemicals, food-grade oils, and industrial solvents rely on tight head steel drums for the safe movement of bulk liquids. Their robust, welded construction ensures resistance to impact, corrosion, and pressure fluctuations.

- Optimal for liquids, oils, and chemicals

- Leak-proof design meets stringent safety standards

- Customizable linings (epoxy, phenolic) for enhanced chemical resistance

- UN/DOT approved for hazardous materials transport

Salvage Drums (Overpack Drums)

Salvage drums, also called overpack drums, are engineered for secondary containment of leaking, damaged, or non-compliant containers. Constructed from heavier gauge steel, they feature reinforced walls, robust closures, and high-capacity seals to contain spills and prevent environmental contamination.

Salvage drums are a regulatory requirement for the transportation and disposal of hazardous waste under OSHA and EPA guidelines. They’re commonly used in emergency spill response, chemical clean-up operations, and waste management facilities. Customization options include drainage fittings, vapor-tight closures, and specially formulated liners for compatibility with aggressive chemicals.

- Meets U.S. Department of Transportation (DOT) and UN standards for salvage packaging

- Protects workers and the environment from hazardous material leaks

- Available in various sizes and thicknesses for specialized containment needs

- Can be reused or recycled in accordance with environmental regulations

Need help choosing between open head, tight head, or salvage drums for your material handling needs? Request a quote.

Key Considerations When Using Steel Barrels

While steel barrels offer outstanding durability and versatility, several important factors should be assessed before selecting the optimal drum for your operation:

- Environmental Impact: Steel barrels are recyclable, but improper disposal can contribute to landfill waste. Many suppliers now offer reconditioned steel barrels to reduce environmental impact and support sustainability initiatives.

- Corrosion Resistance: Without protective linings, steel drums may corrode when exposed to certain chemicals or moisture. Choosing the right interior lining (epoxy, phenolic, or FDA-compliant food-grade coatings) is critical for product integrity.

- Weight and Handling: Steel barrels are heavier than plastic or fiber alternatives. Considerations for material handling equipment, such as drum dollies, forklifts, or palletizers, may be necessary for safe movement and storage.

- Regulatory Compliance: For hazardous materials, ensure that drums are UN-rated and meet all DOT/OSHA regulations. Proper documentation and labeling are essential for legal compliance and workplace safety.

- Cost and Lifecycle: Although steel drums have a higher upfront cost than plastic drums, their durability and reusability often result in a lower total cost of ownership over time. Explore drum reconditioning and refurbishment services to extend the lifespan of your investment.

Wondering whether steel barrels are the right choice for your product or waste stream? Compare steel vs. plastic barrels or speak to a specialist for a tailored recommendation.

Benefits of Steel Barrels: Why Choose Steel Over Alternative Materials?

Steel barrels remain one of the most popular packaging and transportation solutions in global commerce, thanks to their distinctive advantages:

- Exceptional Durability: Steel drums can withstand rough handling, stacking, and extreme temperatures. Their resistance to punctures and impacts makes them suitable for demanding industrial environments.

- Reusable and Reconditionable: Unlike single-use packaging, steel barrels can be reconditioned, cleaned, and reused multiple times, reducing both procurement costs and environmental impact.

- Versatility: Steel barrels are effective for storing and transporting a variety of materials, including liquids, powders, hazardous substances, and even food-grade products (with appropriate linings).

- Customizability: With a wide range of fittings, closures, gaskets, and interior coatings, steel drums can be adapted to virtually any application.

- Sustainability: Steel is the world’s most recycled material. Most steel barrels are manufactured from recycled steel and can be recycled again at the end of their usable life.

- Regulatory Acceptance: Steel drums are widely recognized and approved by international standards bodies (UN, DOT, ISO), making them a trusted choice for transporting regulated goods.

Common Applications and Industries Served by Steel Barrels

Thanks to their strength, customizability, and compliance with global standards, steel barrels are deployed across a wide array of industries and applications:

Storage and Transport of Dry Goods

Steel barrels are widely used for the secure storage and movement of dry bulk materials, such as grains, powders, minerals, and machine parts. Their rigidity protects contents from external contamination and damage during transit. Open head designs offer easy access for loading and unloading bulk materials.

Chemicals and Industrial Liquids

The chemical processing and distribution sectors rely on steel drums to store and ship acids, solvents, resins, lubricants, and cleaning agents. With specialized linings, steel barrels protect contents from corrosion and ensure product purity. Tight head drums provide leak-proof containment for hazardous and volatile substances.

Hazardous Materials and Waste Disposal

Steel salvage drums are mandated for spill containment, hazardous waste clean-up, and the safe transport of leaking or damaged containers. Their robust construction and compliance with UN/DOT packaging standards make them indispensable in environmental services and emergency response industries.

Food and Beverage Industry

With FDA-approved coatings, steel barrels are used to store and transport edible oils, syrups, flavorings, and certain food ingredients. Their impermeability and ease of sterilization ensure food safety and prevent cross-contamination.

Oil, Gas, and Energy Sector

Steel barrels are the preferred packaging for fuels, lubricants, hydraulic fluids, and petrochemical products. Their pressure resistance and compatibility with hazardous liquids make them essential for upstream, midstream, and downstream oil and gas operations.

Pharmaceuticals and Specialty Chemicals

High-purity and sensitive compounds require containers that are non-reactive and tamper-resistant. Steel barrels with specialized linings (such as phenolic or epoxy) safeguard pharmaceutical intermediates and specialty chemicals from degradation, contamination, and unauthorized access.

Paints, Coatings, and Adhesives

The paints and coatings industry uses steel drums to transport and store both water-based and solvent-based products. The drums’ robust seals and vapor-tight closures help prevent evaporation, spillage, and environmental hazards.

Factors to Consider When Purchasing Steel Barrels

Selecting the right steel barrel for your needs involves evaluating several critical factors to ensure safety, compliance, and operational efficiency. Here are some key considerations for buyers and procurement specialists:

- Material Thickness and Grade: Thicker gauges offer greater durability and are suitable for heavy-duty or hazardous applications. Verify the steel grade for compatibility with your intended contents.

- Drum Capacity: Steel barrels are most commonly available in 55-gallon (208-liter) sizes, but other capacities (30-gallon, 85-gallon, etc.) are available for specialized uses.

- Lining and Coating Requirements: Consider the chemical compatibility of your product with available drum linings (unlined, epoxy, phenolic, zinc, etc.). Food and pharmaceutical products may require FDA-compliant coatings.

- Closure and Fitting Options: Choose from open head, tight head, or salvage designs, and specify bung size, gasket materials, and venting needs based on your process.

- Regulatory and Certification Needs: For hazardous or export shipments, ensure your steel barrels carry all required certifications (UN, DOT, ISO).

- Supplier Reputation and Service: Partner with suppliers that offer documented quality control, reliable lead times, and responsive support.

Ready to compare steel barrel suppliers? Use our supplier directory to review detailed business profiles, explore areas of specialization, and connect directly with top-rated manufacturers.

Choosing the Right Steel Barrel Supplier: Your Path to Reliable Supply

To achieve optimal results when sourcing steel barrels, it’s crucial to partner with a reputable, experienced supplier who understands your industry’s specific requirements. Whether you need standard 55-gallon drums, custom fittings, or specialized linings, the right supplier can ensure product integrity, regulatory compliance, and on-time delivery.

How can you efficiently evaluate and select the best steel barrel manufacturer?

- Explore Our Supplier Directory: Each steel barrel supplier in our comprehensive directory has a dedicated business profile page detailing their experience, capabilities, and value-added services. Use our website previewer to quickly assess specialties and certifications.

- Request Multiple Quotes: Our simple RFQ form allows you to contact multiple suppliers at once, helping you compare pricing, lead times, and customization options.

- Assess Customer Service: Look for suppliers with a track record of responsive support, technical expertise, and a willingness to provide documentation, test results, or compliance certificates.

- Consider Logistics and Delivery: Factor in shipping costs, delivery schedules, and geographic location to minimize lead times and ensure uninterrupted supply.

Have questions about steel barrel sourcing, compliance, or customization? Contact our team for personalized assistance or request a quote now.

Frequently Asked Questions About Steel Barrels

- What is the difference between open head and tight head steel barrels? Open head drums have removable lids for easy access, best for solids and viscous materials. Tight head drums are sealed with small bung openings, ideal for liquids and volatile substances.

- Are steel barrels suitable for food-grade applications? Yes, with proper FDA-approved linings, steel barrels can safely store and transport food products and ingredients.

- How can steel barrels be recycled or reconditioned? Most steel barrels can be cleaned, refurbished, and reused multiple times. At end-of-life, they are fully recyclable in steel recycling programs.

- How do I select the right lining for my steel drum? Consult with your supplier or review chemical compatibility charts to choose between unlined, epoxy, phenolic, or specialty linings based on product requirements.

- What certifications should I look for in a steel barrel? For hazardous materials, look for UN, DOT, and ISO certifications to ensure regulatory compliance and shipment acceptance.

55 Gallon Drums

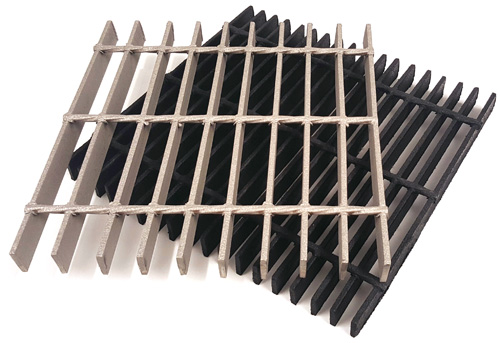

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services