The plastic pail or bucket is a very common tool found around the house, in industrial and manufacturing facilities, and as a part of cleaning equipment. Originally, pails were made of metal or wood and were a bit cumbersome. With the technological advancements and innovations of plastic molding and processing, a new form of pail arose made from plastic. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

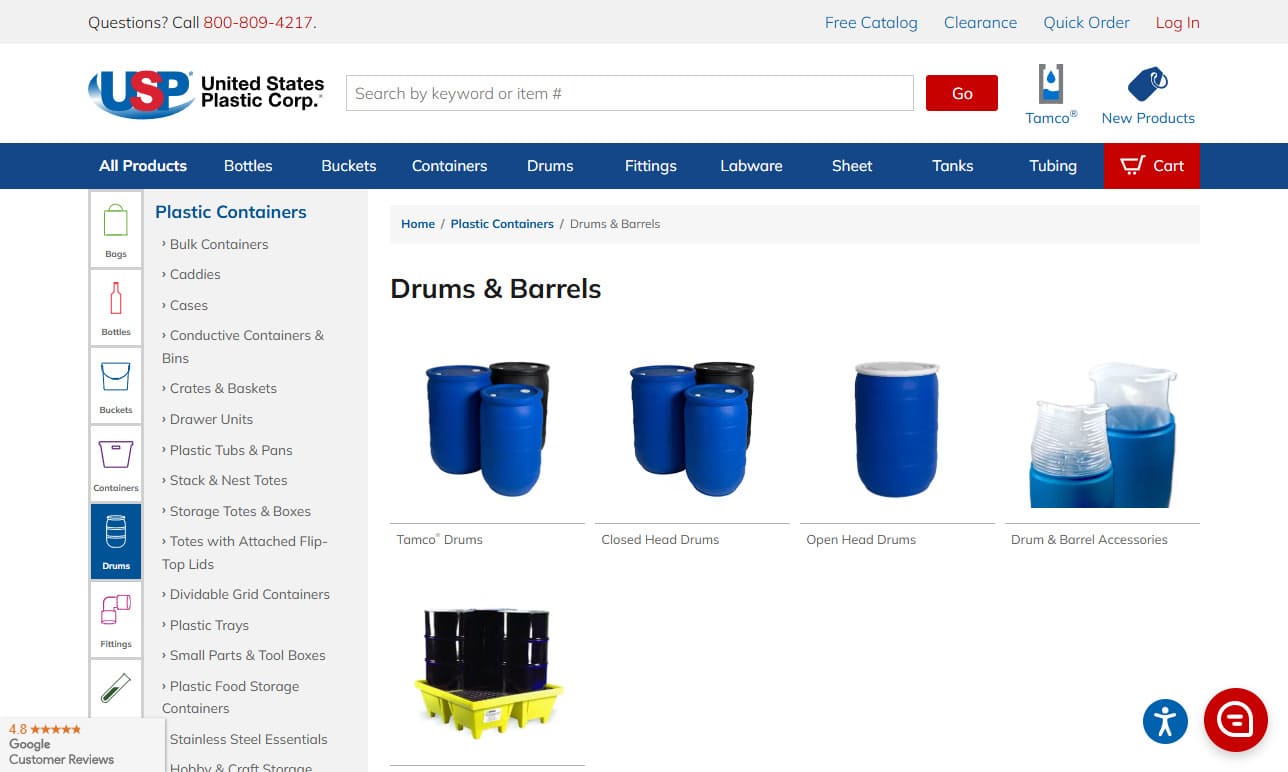

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Plastic Pail Manufacturers

A typical bucket or pail is shaped like a cylinder with vertical rounded sides, a flat bottom, and no top. In many ways, it very much resembles a tiny barrel or drum. For convenience, pails feature a half-circle handle made of plastic or lightweight metal, making them easy to lift and carry. These versatile containers are essential tools in industrial, commercial, and residential settings, offering practical solutions for storage, transport, and application of liquids, powders, granules, and more.

What is a Plastic Pail?

A plastic pail is a small watertight container that can typically hold between one gallon (approximately 3 liters) and as many as 13 gallons (about 50 liters) of material. While the traditional shape is cylindrical, there are numerous configurations designed to meet specific needs—including options with slightly slanted sides for easy stacking or variants with a closed head (sealed top) for secure transport and storage of sensitive materials. Plastic pails are widely used across industries such as food processing, chemical manufacturing, pharmaceuticals, agriculture, construction, and janitorial services.

The most common plastic pail design features an open top to allow for easy access, pouring, scooping, or mixing. This makes plastic pails ideal for storing and transporting liquids, chemicals, paints, adhesives, cleaning agents, and granular materials such as sand, salt, or pet food. Their lightweight construction ensures that they can be conveniently positioned under a faucet for filling, or moved from place to place as needed. The combination of durability, chemical resistance, and portability makes plastic pails a go-to choice for both professional and household applications.

For specialized uses, closed head plastic pails are available. These pails have a lid permanently attached to the top, often featuring one or two small plugs (bungs) for filling and dispensing. Closed head designs are engineered primarily for the storage and shipping of hazardous or volatile liquids, such as industrial chemicals, solvents, and oils, ensuring leak-proof containment and safe transit. While they offer superior protection and spill resistance, closed head pails are generally less flexible than open head variants in terms of accessibility and reuse.

Key Benefits of Plastic Pails

- Lightweight and Portable: Easy to carry, transport, and handle, even when full.

- Corrosion and Chemical Resistance: Suitable for storing a broad range of substances, including corrosives and sensitive chemicals.

- Reusable and Recyclable: Many plastic pails can be reused multiple times or recycled at the end of their lifecycle.

- Customizable Features: Options include tamper-evident lids, spouts, and color-coding for product identification.

- Cost-Effective: More affordable and longer lasting than many alternative materials, such as metal or glass.

Typical Applications and Industries Using Plastic Pails

- Food Industry: Storage and transport of ingredients, syrups, sauces, and bulk foodstuffs.

- Chemicals and Pharmaceuticals: Safe containment of hazardous or sensitive materials.

- Construction: Mixing and carrying adhesives, paints, and building materials.

- Agriculture: Holding fertilizers, animal feed, and water supplies.

- Cleaning and Janitorial: Buckets for mopping, mixing cleaning agents, and waste collection.

- Industrial Manufacturing: Handling lubricants, coatings, and powdered goods.

Are you searching for the best plastic pail for your application?

Consider the specific requirements of your industry, material compatibility, desired capacity, and regulatory compliance before making a purchase. What size and type of plastic pail fits your storage, transport, or mixing needs? Explore different lid options, handle types, and available certifications (such as FDA, UN, or NSF ratings) to ensure you select the right product for your business or home.

How Plastic Pails are Made

The process for manufacturing a plastic container—whether a barrel, drum, bucket, or pail—is called blow molding. Blow molding uses a polymer resin, such as high-density polyethylene (HDPE) or polypropylene, to form the container. The most important characteristic of these pails is their watertight, airtight seal, which prevents leaks and protects contents from contamination. This is achieved by shaping the pail as a single, seamless piece of plastic through the blow molding process.

The manufacturing of plastic pails begins with the creation of a hollow plastic tube known as a parison or preform. This parison is positioned between two metal dies, each with the shape and dimensions of the final pail. Pressurized air is then blown into the molten plastic, forcing it against the walls of the die cavity. As the plastic cools and solidifies, it retains the desired shape. Once hardened, the pail is ejected from the mold, ready for finishing and quality checks.

This technique allows for rapid, high-volume production. In fact, thousands of plastic pails can be manufactured per hour using automated blow molding lines. The process also ensures uniform wall thickness and a consistently strong seal for every unit, meeting demanding standards for use in industrial, commercial, and food-grade applications.

Why is Blow Molding Preferred for Plastic Pails?

- Seamless Construction: Eliminates weak points and reduces risk of leaks or contamination.

- Efficient Production: Supports large-scale manufacturing and cost-effective pricing.

- Design Flexibility: Enables customization of features such as handles, spouts, and stacking lugs.

- Consistent Quality: Automated controls ensure every pail meets strict performance and safety criteria.

Alternative Manufacturing Methods for Plastic Pails

While blow molding is the most prevalent technique, other methods such as injection molding and rotational molding may also be used for certain pail designs, especially when precise dimensional accuracy or complex shapes are required. These processes may be chosen for specialty items, custom branding, or applications demanding thick-walled, impact-resistant pails.

Materials Used to Make Plastic Pails

Choosing the right plastic resin is critical for achieving the necessary strength, durability, and chemical compatibility in pail manufacturing. The most common plastics used are thermoplastics, which are both pliable and ductile—ideal for melting, shaping, and molding into a variety of container forms. Some of the leading materials include:

- High-Density Polyethylene (HDPE): Known for its excellent strength-to-density ratio, HDPE is the industry standard for most plastic pails due to its toughness, chemical resistance, and food safety certifications. Explore the benefits of HDPE pails for food, chemicals, and more.

- Polypropylene (PP): Offers high resistance to heat and fatigue, making it suitable for applications involving hot liquids, autoclaving, or repeated use.

- Polyvinyl Chloride (PVC): Used for its flexibility and resistance to oils and chemicals, though less common in food applications due to regulatory concerns.

- Polystyrene (PS): Lightweight and rigid, but generally reserved for dry goods and less demanding environments.

- Polyethylene Terephthalate (PET): Valued for clarity, impact strength, and use in transparent or semi-transparent pail designs.

- Polycarbonate (PC): Offers exceptional toughness and clarity, suitable for specialty and industrial-grade containers.

The selection of material depends on the intended use, exposure to chemicals, temperature requirements, and regulatory standards. For example, food-grade plastic pails require FDA-approved resins free from contaminants, while hazardous material pails may need UN/DOT certification for shipping chemicals or solvents.

Are Plastic Pails Environmentally Friendly?

Many of the plastics used in pail production are chosen for their ability to be reused and recycled. HDPE and polypropylene, in particular, are easily processed through recycling programs, allowing for sustainable lifecycle management. If your business prioritizes environmental stewardship, consider selecting pails made from recycled content or certified for recyclability. Learn more about eco-friendly plastic pail options and recycling programs.

Factors to Consider When Selecting Plastic Pails

- Capacity and Dimensions: What volume do you need—gallon, liter, or custom size?

- Material Compatibility: Will the pail safely store your chemicals, food products, or industrial materials?

- Handle Type and Ergonomics: Is the handle comfortable and strong enough for your application?

- Lid Options and Sealing: Do you need an airtight, watertight, or tamper-evident lid?

- Stackability and Storage: Will the pails nest or stack securely for efficient storage and transport?

- Compliance and Certification: Are certifications such as FDA, UN, or NSF required for your industry?

- Customization: Do you require printed logos, color coding, or specialty spouts?

Comparing different plastic pail suppliers and manufacturers can help you find the ideal product at the best value. Are you looking for wholesale plastic pails for bulk purchasing? Or do you need a custom solution for unique industrial packaging requirements?

Plastic Pail Buying Guide: Choosing the Right Container for Your Needs

When researching and evaluating plastic pails for purchase, it's important to align your choice with both application and regulatory needs. Here are some common questions and prompts to help guide your decision-making process:

- What will you store? Identify whether you need a pail for food, chemicals, paint, water, or other materials.

- How will you use the pail? Consider if you'll be mixing, storing, transporting, or dispensing contents regularly.

- Is chemical compatibility required? Ensure the pail material resists corrosion or chemical reactions with your product.

- Do you need a specific lid type? Choose from snap-on, screw-on, tamper-evident, or spouted lids based on security and access needs.

- Are there temperature extremes? Make sure the plastic can withstand freezing or elevated temperatures without degrading.

- Is regulatory compliance essential? Look for FDA, NSF, or UN-rated pails for food, pharmaceutical, or hazardous material applications.

- What about branding or color coding? Ask suppliers about custom colors, labels, or printing options for easy identification.

How to Maintain and Reuse Plastic Pails

Extending the lifespan of your plastic pails through proper cleaning and maintenance enhances sustainability and reduces costs. Here are some tips for getting the most value from your containers:

- Rinse thoroughly after each use, especially if storing food, chemicals, or hazardous materials.

- Avoid harsh abrasives that can scratch or weaken the plastic.

- Store pails in a cool, dry place to prevent UV degradation and warping.

- Inspect handles and lids regularly for signs of wear or damage before reuse.

- Participate in manufacturer recycling programs or return empty pails for responsible disposal.

Interested in best practices for cleaning and reusing plastic pails? Discover expert tips for maximizing the life and value of your plastic containers.

Sustainability and Recycling of Plastic Pails

Modern consumers and businesses increasingly value eco-friendly packaging. Many plastic pails are now produced from post-consumer recycled (PCR) plastics or designed for full recyclability. When selecting pails, check for recycling symbols and certifications to ensure your containers can enter established recycling streams at end-of-life. Some suppliers offer take-back or closed-loop recycling programs to help you minimize environmental impact.

Additionally, lightweight plastic pails require less material and energy to produce and transport compared to metal or glass alternatives, contributing to reduced carbon emissions. By reusing plastic pails multiple times and recycling at the end of their life, companies can support circular economy initiatives and achieve sustainability goals.

Ready to Switch to Sustainable Plastic Pails?

Contact suppliers to ask about pails made from recycled content, biodegradable plastics, or those participating in closed-loop recycling. Find out how eco-conscious packaging can benefit your business and the environment.

Frequently Asked Questions About Plastic Pails

- What is the difference between a bucket and a pail? In most cases, the terms are used interchangeably, but "pail" is more common in industrial and packaging contexts, while "bucket" is often used for household applications.

- Are all plastic pails food safe? Only pails manufactured from FDA-approved, food-grade plastics are suitable for direct food contact. Always verify certifications with suppliers before purchasing for food applications.

- Can plastic pails be used for hazardous chemicals? Yes, but only if constructed from compatible materials and carrying appropriate UN/DOT certification for hazardous material storage and transport.

- How do I choose the right lid for my plastic pail? Consider your needs for security, access, and leak prevention. Options include snap-tight, screw-on, tamper-evident, and vented lids.

- What is the shelf life of a plastic pail? With proper care, plastic pails can last for years, though exposure to sunlight, harsh chemicals, or extreme temperatures may reduce lifespan.

Still have questions about plastic pails, buckets, or industrial packaging solutions? Contact us for expert advice and product recommendations.

Conclusion: The Versatility and Value of Plastic Pails

Plastic pails are indispensable tools for professionals and homeowners alike, combining lightweight durability, chemical resistance, and cost-effectiveness. Whether you need bulk storage for food products, secure containers for hazardous chemicals, or portable mixing solutions for construction, there is a plastic pail tailored to your requirements. Advances in blow molding technology, material science, and sustainable manufacturing ensure that today’s plastic pails provide superior performance while supporting environmental responsibility. For the best results, always select pails that match your specific application, regulatory needs, and sustainability objectives.

Ready to buy high-quality plastic pails or buckets for your next project? Browse a selection of top-rated plastic pail suppliers or request a custom quote today to find the right solution for your storage, transport, or packaging needs.

55 Gallon Drums

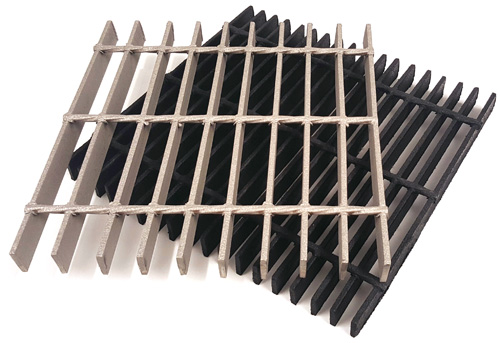

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services