Plastic drums are the most versatile equipment found in warehouses for the storage and transporting of materials. Plastic drums are generally blue with a spherical shape, and their sizes may vary accordingly. These drums are used in many industries for the storage of hazardous materials as well as for foodstuff. Plastic drums are made from a material known as HDPE, a malleable and rigid material that can withstand high temperatures and chemicals. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Plastic Drum Manufacturers

Plastic drums are indispensable in modern industrial packaging, offering versatile and cost-effective solutions for storing and transporting a wide variety of liquids, solids, and hazardous materials. Their popularity spans sectors such as the chemical industry, food processing, pharmaceuticals, agriculture, and even rainwater harvesting applications. Selecting the right plastic drum is essential for ensuring safety, regulatory compliance, and operational efficiency. This guide provides an in-depth look at plastic drum sizes, types, materials, manufacturing processes, key applications, and expert tips for choosing a reputable plastic drum manufacturer.

Plastic Drum Sizes: Meeting Diverse Industrial Needs

The sizes of plastic drums vary according to the requirements of different industries and applications. Standard plastic drum capacities typically range from 30-liter barrels up to large 220-liter (55-gallon) drums. The larger, industrial-grade plastic drums are designed for bulk storage and can be easily handled with forklifts, optimizing logistics in warehouses and shipping environments. Conversely, smaller plastic drums and barrels are often equipped with ergonomic side handles, allowing safe and convenient manual handling in laboratories, small-scale manufacturing, or on-site operations.

Are you wondering which plastic drum size is best suited to your specific needs? Consider the following factors:

- Volume requirements: Estimate the quantity of liquid, powder, or granule you need to store or transport.

- Handling method: Will you use forklifts, pallet jacks, or manual lifting?

- Storage space: Assess your available warehouse or shelving space for optimal drum dimensions.

- Regulatory compliance: Certain applications (e.g., hazardous waste storage) may require specific drum types and sizes.

For more detailed guidance, explore our applications section to match drum sizes to common industry use cases.

Types of Plastic Drums: Open-Head vs. Tight-Head

Understanding the types of plastic drums is critical for selecting the right packaging solution for your materials. There are two primary categories:

Open-Head Plastic Drums

Open-head plastic drums (also known as removable top drums) feature a detachable lid secured with a steel or plastic clamp ring. This design makes them ideal for applications that require frequent access, filling, or dispensing of contents. Open-head barrels are widely used for storing solids, semi-solids, viscous liquids, powders, and materials that may need to be mixed or sampled regularly.

- Easy to open and reseal for repeated use

- Ideal for solid or thick substances, including food ingredients, adhesives, and waste materials

- Available in various sizes and FDA-approved food-grade options

- Compatible with tamper-evident seals for security

Tight-Head (Closed-Head) Plastic Drums

Tight-head plastic drums, also called closed-head barrels, have a permanently sealed top and bottom, with integrated bungs or nozzles for controlled dispensing. The secure, leak-proof design is preferred for transporting and storing hazardous chemicals, flammable liquids, and other sensitive materials that must not be exposed to air or contaminants.

- Superior spill resistance and product protection

- Ideal for storing and shipping industrial chemicals, solvents, and oils

- Equipped with screw caps or vented plugs for easy and safe pouring

- Certified for hazardous material transport (UN/DOT/ADR ratings available)

Not sure whether you need an open-head or tight-head drum for your operation? Ask yourself:

- Will I need to access the contents often?

- Is my product solid, semi-solid, or liquid?

- Do I require maximum leak and tamper resistance?

Types of Plastics Used in Drum Manufacturing

Plastic drums are manufactured using several high-performance polymers, each offering unique chemical compatibility, durability, and environmental benefits. The most common materials used in plastic drum production include:

High-Density Polyethylene (HDPE)

- HDPE (High-Density Polyethylene) is the most popular choice for industrial plastic drums due to its outstanding strength-to-weight ratio, impact resistance, and chemical inertness.

- Commonly used for packaging chemicals, pharmaceuticals, food products, and potable water.

- Resistant to acids, alkalis, alcohols, and many solvents, making it ideal for hazardous material storage.

- Lightweight, easy to handle, and highly recyclable, supporting sustainability initiatives.

- Complies with FDA, USDA, and UN regulations for food and hazardous goods transport.

Polyvinyl Chloride (PVC)

- PVC (Polyvinyl Chloride) drums are valued for their rigidity, flame resistance, and chemical compatibility with aggressive substances.

- Suitable for storing flammable, corrosive, or toxic chemicals in industrial settings.

- Offers reliable containment of volatile organic compounds and hazardous waste.

Nylon

- Nylon drums provide excellent non-reactivity, low moisture absorption, and high mechanical strength.

- Preferred for specialty applications requiring resistance to abrasion and certain solvents.

Polystyrene

- Polystyrene is a thermoplastic valued for its lightweight properties and ease of molding.

- Used in the production of disposable and single-use containers, not typically for high-risk chemical storage.

Looking for food-grade plastic drums or drums for hazardous waste? Check our applications section for material recommendations by industry.

Plastic Drum Manufacturing Processes: How Are Plastic Drums Made?

Modern plastic drum manufacturing utilizes advanced molding techniques to ensure product consistency, structural integrity, and compliance with stringent quality standards. The three primary manufacturing processes for plastic drums are:

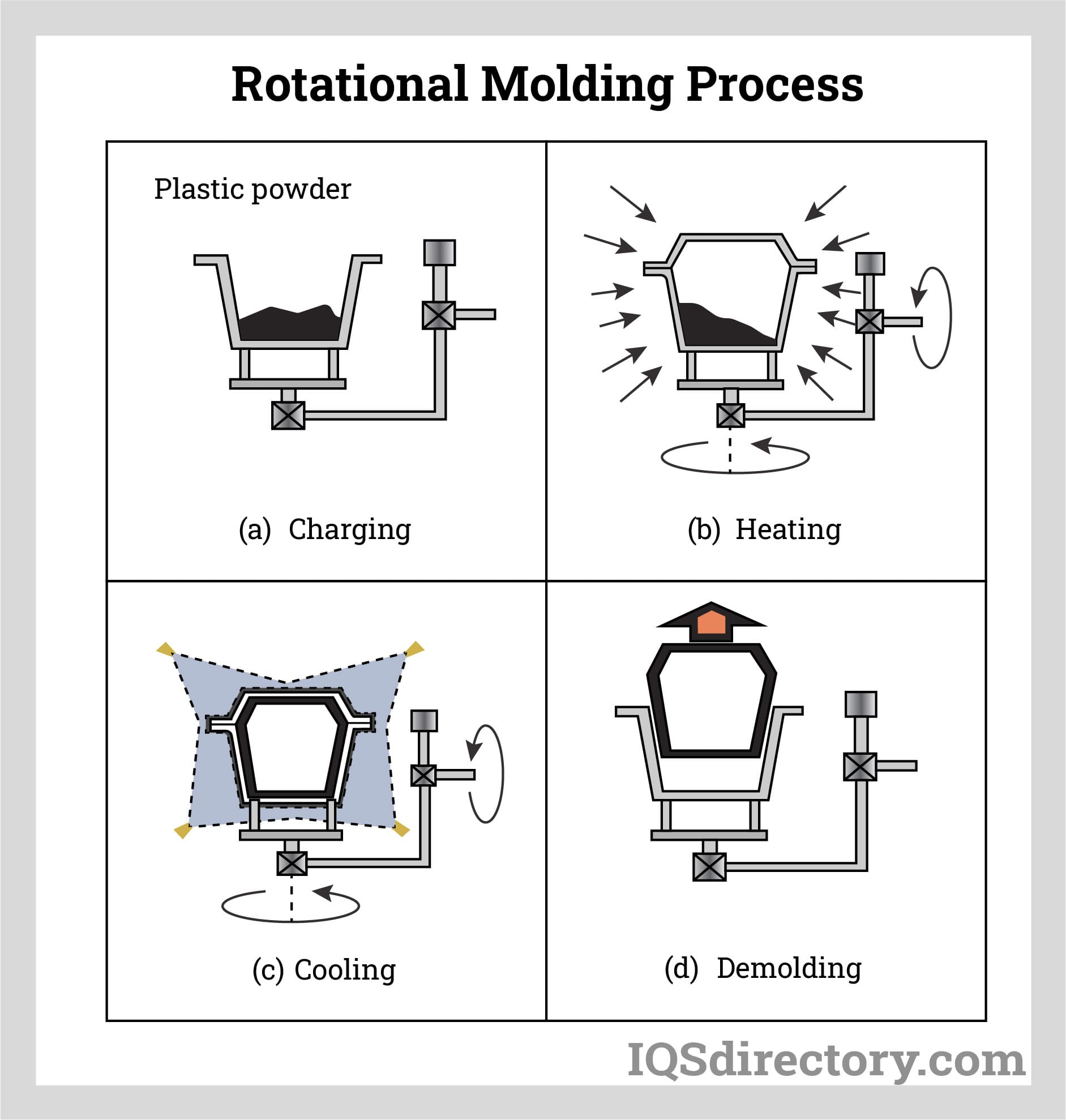

Rotational Molding (Rotomolding)

- Ideal for producing large, seamless, and hollow products such as industrial drums and tanks.

- Process involves loading powdered polymer (usually HDPE) into a mold, heating while rotating on multiple axes, and then cooling to form a uniform, stress-free drum body.

- Offers excellent wall thickness distribution and strength for heavy-duty applications.

- Cost-effective for low to medium production volumes and custom shapes.

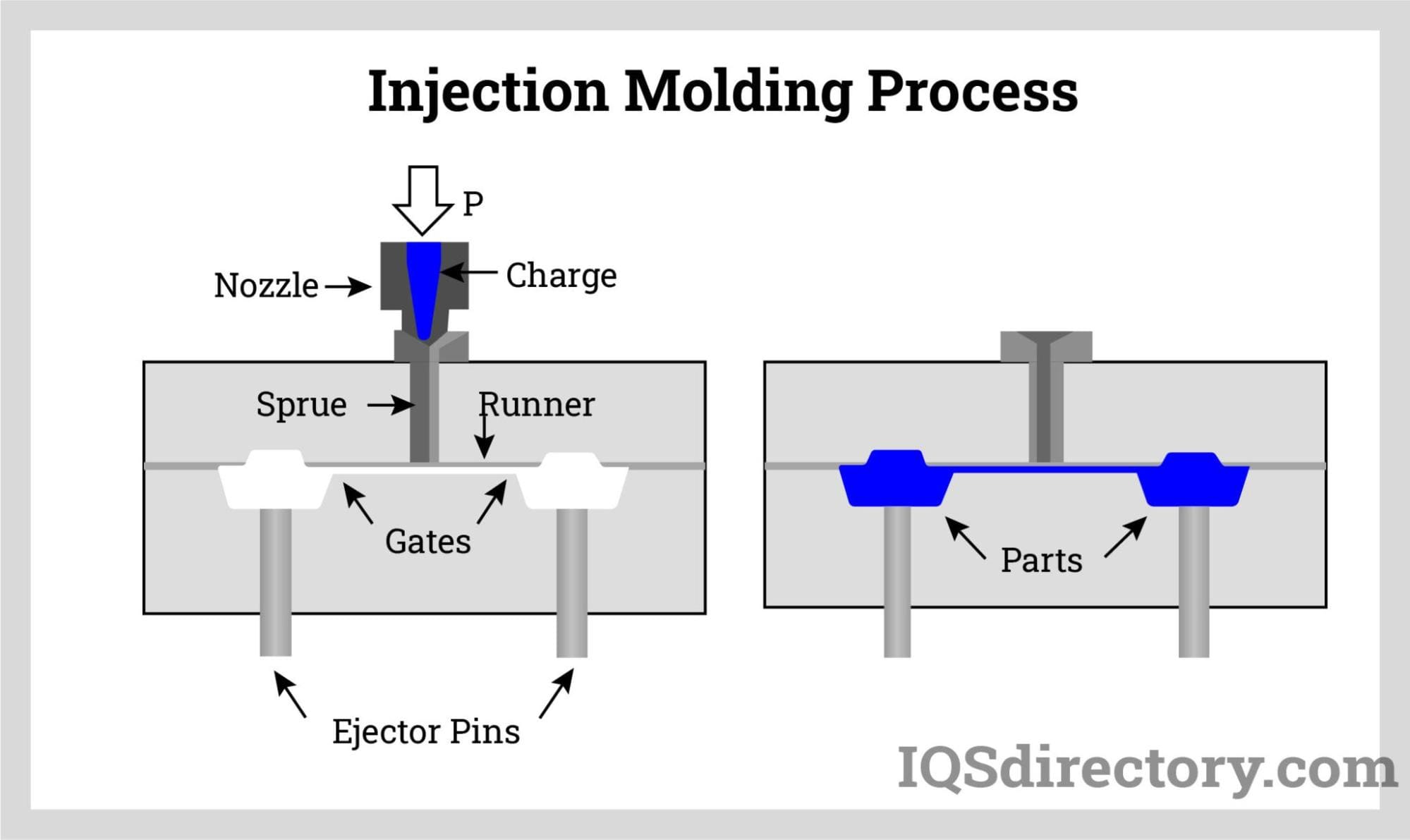

Injection Molding

- Best suited for producing smaller, high-precision drum components such as lids, bungs, caps, and accessories.

- Molten polymer is injected into a steel mold under pressure, forming complex shapes with tight tolerances.

- Allows for rapid, high-volume production and customization of drum features.

- Ensures consistent quality and dimensional accuracy for drum closures and fittings.

Injection Blow Molding

- Injection blow molding is the leading process for manufacturing seamless, hollow plastic drums, bottles, and containers.

- The method combines injection molding and blow molding, first forming a preform (parison) and then inflating it into the final drum or container shape.

- Ensures uniform wall thickness, leak-proof seams, and high mechanical strength.

- Ideal for producing UN-certified drums for hazardous and regulated materials.

Curious about which manufacturing process is best for your application? Ask:

- Do I need custom shapes or standard drum sizes?

- Is seamless construction required for leak prevention?

- What are my volume and budget constraints?

Applications & Use Cases for Plastic Drums

Plastic drums are trusted across a spectrum of industries due to their durability, chemical resistance, and regulatory compliance. Here are some of the most common plastic drum applications:

- Chemical storage and transport: Safely contain acids, bases, solvents, detergents, and hazardous waste—ideal for manufacturing plants and chemical distribution.

- Pharmaceutical and medical supplies: Ensure contamination-free transport of active ingredients, bulk medications, and healthcare products with FDA-approved food-grade drums.

- Food and beverage processing: Store grains, syrups, edible oils, flavorings, and dry condiments in sanitary, food-safe plastic barrels that resist corrosion and contamination.

- Oil and lubricants industry: Efficiently store and dispense engine oils, greases, and industrial lubricants with tamper-evident, leak-proof drums.

- Agriculture and horticulture: Collect rainwater, store fertilizers, pesticides, and animal feed in UV-resistant plastic drums designed for outdoor use.

- Water storage and emergency preparedness: Use potable water drums for disaster relief, emergency response, and long-term water storage solutions.

- Waste management and recycling: Safely segregate, store, and transport industrial waste, e-waste, and recyclable materials in color-coded or labeled drums.

- Paints, coatings, and adhesives: Package and transfer volatile or sensitive substances in drums engineered for chemical compatibility and secure sealing.

Which plastic drum application fits your business needs? If you need help selecting the right drum for your industry, connect with our experts or use our decision prompts below:

- Do you require UN-certified drums for hazardous materials?

- Is food safety certification a priority for your operation?

- Are you looking for stackable, space-saving designs for warehouse efficiency?

- Do your products require special color-coding or labeling for regulatory compliance?

Advantages and Benefits of Plastic Drums

Plastic drums offer a host of benefits over traditional steel drums, fiber barrels, or other packaging containers. Key advantages include:

- Corrosion resistance: Unlike steel drums, plastic drums do not rust or corrode, ensuring long-term storage integrity for chemicals, food, and water.

- Lightweight and ergonomic: Easier to handle, transport, and stack, reducing manual handling injuries and shipping costs.

- Chemical compatibility: Suitable for a wide range of acids, bases, and solvents, minimizing the risk of chemical reactions or product contamination.

- Reusability and recyclability: Many HDPE drums are reusable and recyclable, supporting sustainability and cost-saving initiatives.

- Customizable designs: Available in various colors, sizes, and with options for labeling, embossing, and tamper-evident features.

- Compliance with industry standards: FDA, USDA, UN, and DOT certifications are available for food, pharmaceutical, and hazardous material transport.

- UV and weather resistance: Outdoor-rated drums resist sunlight and temperature extremes, suitable for agriculture and emergency water storage.

- Stackability and space efficiency: Many plastic drums are designed for secure stacking, saving valuable warehouse or shipping space.

Plastic Drum Accessories & Customization Options

Enhance the performance and functionality of your plastic drums with a wide range of accessories and custom features:

- Spigots, faucets, and valves: Facilitate controlled dispensing of liquids.

- Bungs and closures: Provide secure, leak-proof sealing for tight-head drums.

- Drum liners: Add an extra layer of protection for sensitive or cross-contaminating contents.

- Color coding and labeling: Simplify inventory management and regulatory compliance.

- UN/DOT-approved labeling: Meet legal requirements for hazardous material shipping.

- Stackable pallets and drum cradles: Optimize storage and transport efficiency.

- Tamper-evident seals: Ensure product security during transit.

Need a specific drum accessory or custom feature? Contact our team for tailored recommendations.

How to Choose the Right Plastic Drum Manufacturer

Selecting a reputable plastic drum manufacturer is crucial for ensuring product quality, regulatory compliance, and reliable supply. Here’s how to make an informed decision:

- Compare multiple suppliers: Evaluate at least 5 or 6 companies using our Plastic Drums directory to review their product lines, certifications, and customer reviews.

- Check areas of expertise: Each manufacturer’s profile highlights their core competencies, such as food-grade drums, hazardous material containers, or custom drum solutions.

- Request samples and certifications: Ask for product samples, quality control documentation, and regulatory certifications to verify suitability for your application.

- Assess customer service and support: Use our contact form to communicate directly with manufacturers for technical assistance, bulk pricing, or lead time information.

- Utilize our patented website previewer: Get a visual overview of each supplier’s facility, manufacturing processes, and product range.

- Submit an RFQ (Request for Quote): Use our simple RFQ form to contact multiple plastic drum companies simultaneously with your requirements.

What questions should you ask a potential plastic drum supplier?

- Can you provide documentation for FDA, UN, or DOT certifications?

- Do you offer custom sizes, colors, or labeling options?

- What are your minimum order quantities and lead times?

- How do you ensure quality control during production?

- Do you provide technical support for selecting the correct drum for my application?

Frequently Asked Questions About Plastic Drums

Looking for quick answers? Here are some common queries from buyers and industry professionals:

- Are plastic drums safe for food storage? Yes, when made from FDA-approved HDPE or other food-grade plastics, they are safe for storing food and potable water.

- How long do plastic drums last? With proper care, plastic drums can last 10-20 years, depending on exposure to UV light, chemicals, and handling conditions.

- Can plastic drums be recycled? Most HDPE and polypropylene drums are fully recyclable. Check local recycling guidelines for large container disposal.

- What is the difference between blue and white plastic drums? Blue drums typically indicate chemical or industrial use, while white or natural drums are preferred for food or pharmaceutical products to easily detect contamination.

- What is a UN-rated drum? UN-certified drums meet international standards for the safe transport of hazardous materials by road, rail, sea, or air.

- What accessories are available for plastic drums? Common accessories include bungs, valves, liners, drum pumps, and tamper-evident seals.

Ready to Purchase Plastic Drums?

Whether you’re searching for wholesale plastic drums, custom plastic barrels, or food-grade drum containers, our directory connects you with top-rated manufacturers and suppliers across North America, Europe, Asia, and beyond. Browse our plastic drum supplier directory to compare products, request quotes, and find the right solution for your storage and shipping needs.

Still have questions or need personalized advice? Contact our plastic drum experts for tailored recommendations, technical support, and custom quote requests. Our team is committed to helping you select the best plastic drum solution for your industry, ensuring safety, compliance, and value for your business.

55 Gallon Drums

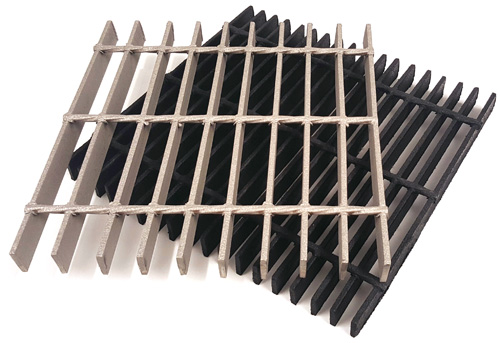

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services