Plastic barrels are spherical drums molded from high-density polyethylene (HDPE). Numerous hazardous items can be stored in plastic barrel drums. These drums are made to properly store and transport materials that must not leak. To seal any hazardous substance, these containers can be paired with sorbents (materials used to absorb liquids and gasses) to avoid leaks. These plastic barrels can also be used for shipping/storing other goods like food, beverages, oils etc. Plastic barrel drums work well as spill containment containers in spill-cleaning scenarios. They are used extensively in both residential and business settings for this purpose. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

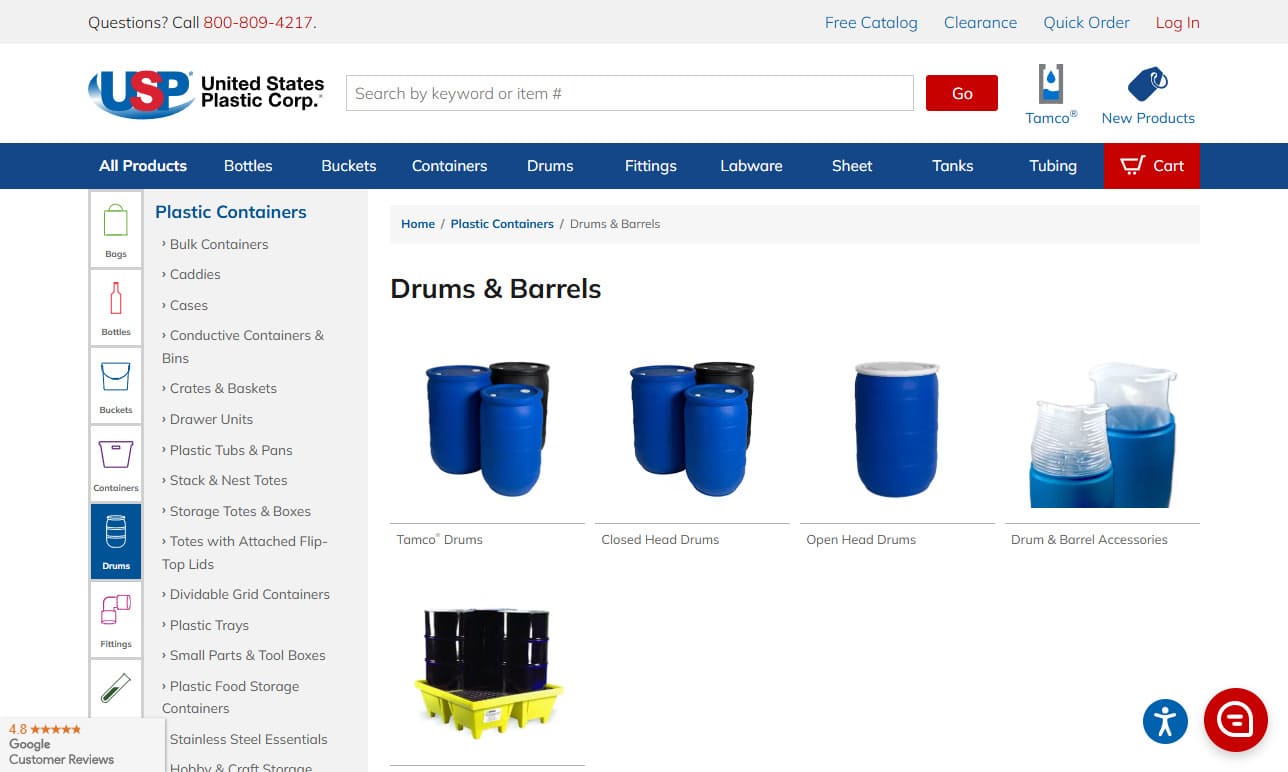

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Plastic Barrel Manufacturers

How Plastic Barrels are Made

Plastic barrels, also known as plastic drums, are essential industrial storage containers used for handling, transporting, and storing liquids and solids across a wide range of industries—such as chemical processing, food and beverage, pharmaceuticals, agriculture, and waste management. The production process for these durable, versatile containers involves careful selection of raw materials and precise manufacturing techniques to ensure quality, safety, and compliance with industry standards.

The selection of the appropriate high-density polymer, typically high-density polyethylene (HDPE), is the first step in the fabrication of plastic barrels. For some specialized applications, low-density polyethylene (LDPE) or other advanced plastics may be chosen. The polymers for barrels begin as resin or pellets, which can be made from recycled plastic for sustainable barrel manufacturing or freshly generated resin from the resin manufacturing process, depending on the type of barrel and its intended use. The most common plastic barrel manufacturing methods are rotational molding, injection molding, and especially injection blow molding, which is recognized for its efficiency and consistency in producing seamless, robust containers.

During the blow molding and injection molding processes, resin pellets are carefully heated and transformed into a malleable state before being introduced into a mold cavity. In rotational molding, resin powder is melted inside the heated mold. Each method offers unique benefits and is selected based on the desired barrel strength, chemical resistance, wall thickness, and intended application.

Rotational Molding Process

Rotational molding, also known as rotomolding, is a popular method for manufacturing large, seamless, and impact-resistant plastic barrels. Unlike injection and blow molding, which use pre-melted resin, rotational molding begins with raw resin powder placed directly into the mold. This powder is not preheated or melted before loading. The process is as follows:

- Preparation: The mold, constructed from robust steel or aluminum, is preconditioned with a release agent to ensure easy removal of the finished drum. Some molds utilize draft angles—slight tapers—to further aid in demolding without the need for additional agents.

- Heating and Rotation: The mold is sealed and rotated simultaneously along two perpendicular axes inside a large oven. As the mold is heated, the resin powder melts and evenly coats the interior surfaces due to centrifugal force and gravity.

- Fusion and Cooling: The molten resin fuses layer by layer, forming a uniform wall thickness. The amount and distribution of resin powder directly determine the barrel's strength, impact resistance, and durability. Once the desired shape and thickness are achieved, the mold is gradually cooled to solidify the barrel, preventing warping and ensuring dimensional accuracy.

- Demolding: The mold is opened, and the finished plastic drum is removed, ready for trimming and quality inspection.

Rotationally molded barrels are highly valued for their seamless construction, making them leak-proof and ideal for critical liquid containment, hazardous waste management, and outdoor storage. This method is particularly suited for producing larger-capacity drums and custom-shaped containers.

Why Choose Rotational Molding for Plastic Barrels?

If you’re considering which manufacturing process suits your needs, rotational molding is ideal when you require exceptional durability, uniform wall thickness, and freedom from weld lines or seams. This makes rotomolded barrels preferable for applications demanding superior containment, such as hazardous chemical storage, rainwater harvesting systems, and agricultural feed bins.

Blow Molding Process

Blow molding is the most widely used technique for manufacturing 55-gallon drums, plastic barrels, and smaller capacity containers. This high-speed, automated process is favored for its ability to produce strong, uniform, and cost-effective barrels in large volumes. Here’s how the blow molding process works:

- Feeding and Melting: Resin pellets, typically HDPE, are loaded into a hopper and conveyed through a heated extruder barrel. The extruder uses rotating screw drives and precise heating elements to melt the pellets into a smooth, consistent parison (a tube-like molten mass).

- Mold Forming: The parison is positioned between two halves of a barrel-shaped mold. The mold closes around the parison, sealing the top and bottom.

- Blowing: Compressed air is injected into the parison, forcing it to expand and conform tightly against the mold walls. This pressure ensures the barrel has a smooth, uniform surface free from air bubbles or weak spots.

- Cooling and Ejection: The mold is cooled by circulating water or air, solidifying the plastic. Once the barrel has set, the mold halves are separated—usually by pneumatic or hydraulic mechanisms—and the finished drum is ejected.

This process is highly efficient and allows for the integration of UN-rated and food-grade barrels, as well as custom color and labeling options. Blow molded drums are widely used for the storage and transportation of chemicals, oils, food ingredients, pharmaceuticals, and potable water.

Advantages of Blow Molded Plastic Barrels

- Cost-Effective Mass Production: Blow molding enables high-speed, large-volume production, reducing unit costs for industrial and commercial buyers.

- Consistent Wall Thickness: The process produces barrels with uniform walls, critical for reliable containment and stackability.

- Customization: Barrels can be made in various sizes, colors, and with different closure types (open-head, tight-head), and can include anti-static or UV-resistant additives for specialized applications.

Injection Molding in Plastic Drum Manufacturing

Injection molding is less common for large barrels but is widely used for smaller plastic containers and specialized drum components, such as lids and bungs. The process involves injecting molten resin directly into a closed mold cavity, allowing for high precision and the creation of complex shapes and reinforced features. Injection-molded plastic drums are often chosen when exceptional dimensional accuracy or intricate design features are required.

Types of Plastic Barrels and Their Applications

Plastic barrels come in various shapes, sizes, and designs to meet the unique requirements of different industries. The most common configurations include:

- Open-Head Drums: Feature removable lids for easy filling and dispensing of solids, semi-solids, and viscous materials. Commonly used for food ingredients, powders, and hazardous waste collection.

- Tight-Head (Closed-Head) Drums: Have a fixed, non-removable top with bungs for secure storage and transport of liquids, chemicals, and oils. Preferred for high-security containment and leak prevention.

- UN-Rated Barrels: Certified for the safe storage and international transport of hazardous materials, meeting strict United Nations performance standards.

- Food-Grade Plastic Barrels: Manufactured from FDA-approved resins and designed for the safe storage of consumable goods, beverages, and potable water.

- Rain Barrels: Repurposed or specially designed for rainwater collection and water conservation applications.

- Reconditioned/Recycled Plastic Barrels: Used drums that have been cleaned, inspected, and certified for reuse—offering a cost-effective and environmentally friendly solution.

Applications of Plastic Barrels

Plastic barrels are among the most versatile industrial containers available, serving a diverse range of industries. Below are some of the primary use cases and applications for plastic barrels and drums:

- Chemical Storage and Transportation: Plastic barrels are the safest and most dependable solution for storing and transporting chemicals, solvents, corrosive substances, and hazardous materials. Their design ensures protection from external environmental conditions, severe heat, rust, and corrosion—critical for regulatory compliance and workplace safety.

- Food and Beverage Processing: With the introduction of FDA-approved food grade plastic barrels, the wine, beer, and spirits industries now use polyethylene drums for fermentation, aging, and bulk storage. These barrels are lightweight, easy to clean, and resistant to contamination, making them superior alternatives to traditional wooden or even stainless steel casks.

- Pharmaceuticals and Biotechnology: The pharmaceutical sector relies on high-purity, contaminant-free drums for the secure storage and transport of active ingredients, intermediates, and finished products.

- Agricultural and Horticultural Uses: Farmers use plastic barrels for storing animal feed, fertilizers, pesticides, rainwater, and even for constructing water troughs and composters due to their durability and chemical resistance.

- Water and Waste Management: Plastic barrels are widely utilized for potable water storage, rainwater harvesting, and containment of liquid or solid waste. Their robust construction ensures long-term reliability in both urban and remote settings.

- Industrial Manufacturing: Manufacturing plants employ plastic drums for bulk materials handling, raw ingredient storage, and as containers for process waste and byproducts.

- DIY and Emergency Preparedness: Repurposed barrels serve as emergency water storage tanks, flotation devices, or as components in custom projects such as floating docks and barrel rafts.

Benefits of Using Plastic Barrels

Are you weighing the pros and cons of plastic barrels versus steel drums or fiber drums? Consider these major benefits of choosing plastic barrels for your storage and transportation needs:

- Lightweight Yet Durable: Easier to handle and transport compared to steel barrels, reducing labor costs and transportation expenses.

- Corrosion and Chemical Resistance: Unaffected by rust or corrosive chemicals, plastic barrels are ideal for storing acids, bases, and reactive substances.

- Leak-Proof Construction: Seamless manufacturing methods result in leak-resistant containers, essential for hazardous or valuable liquids.

- Cost-Effective: Lower purchase and maintenance costs compared to alternative materials, plus options for reuse and recycling.

- Customizable: Available in a wide variety of sizes (15, 30, 55, and 60-gallon drums), colors, and with specialized fittings or closures.

- Regulatory Compliance: UN-rated, FDA-approved, and NSF-certified options ensure compliance with international safety and quality standards.

- Environmentally Friendly: Many plastic barrels are produced from recycled materials and can be reconditioned or recycled at the end of their life cycle.

How to Select the Best Plastic Barrel for Your Application

When choosing a plastic barrel, consider the following factors to ensure you select a container that meets your specific requirements:

- Material Compatibility: Verify that the barrel’s polymer is suitable for the chemicals or materials you plan to store. HDPE is the industry standard for most applications due to its broad chemical resistance.

- Capacity and Size: Determine the appropriate volume (e.g., 30, 55, or 60 gallons) based on your handling and storage needs.

- Open-Head vs. Tight-Head: Choose open-head barrels for solids or materials requiring frequent access, and tight-head barrels for secure liquid containment.

- Regulatory Ratings: For hazardous materials or export, select UN-certified barrels. For food or potable water, ensure FDA or NSF certification.

- Color and Additives: Select color-coded barrels for material segregation, or additives such as UV inhibitors for outdoor use.

- Reconditioned vs. New: Consider reconditioned barrels for cost savings and sustainability, but always confirm suitability for your intended use.

Common Questions When Shopping for Plastic Barrels

- What are the best plastic barrels for chemical storage?

- Are food-grade plastic drums safe for drinking water?

- How do I clean and maintain plastic barrels for reuse?

- Can plastic barrels be used outdoors and resist UV degradation?

- What are the differences between open-head and tight-head drums?

- How do I dispose of or recycle old plastic barrels?

- Where can I find certified UN-rated plastic barrels for hazardous materials?

- What is the lifespan of a typical plastic barrel?

Looking for answers to these questions or need a custom solution? Contact a plastic barrel supplier or browse our in-depth guides for expert advice.

Choosing the Right Plastic Barrel Manufacturer

To ensure the best results when sourcing plastic barrels, it’s crucial to partner with a reliable and experienced plastic barrel manufacturer or supplier. Here’s how to streamline your selection process:

- Compare Multiple Suppliers: Evaluate at least 4 or 5 plastic barrel manufacturers using our exhaustive supplier directory. This allows you to compare product ranges, certifications, and customer reviews.

- Company Profiles: Each plastic barrel supplier has a detailed business profile page highlighting their expertise, quality control processes, and production capabilities.

- Request Quotes Easily: Use our direct contact forms to request information, pricing, or a custom quote from multiple suppliers simultaneously—saving time and ensuring competitive offers.

- Review Specializations: Utilize our proprietary website previewer to quickly assess each company’s specialties, such as UN-certified drums, food-grade barrels, or customized colors and fittings.

- RFQ Form: Take advantage of our streamlined RFQ (request for quote) form to reach out to several plastic barrel companies with a single inquiry, outlining your specific requirements and applications.

- After-Sales Support: Consider suppliers that offer support for reconditioning, recycling, or regulatory compliance documentation to maximize the value of your purchase.

Factors to Consider When Selecting a Plastic Barrel Manufacturer

- Certifications: Look for manufacturers with ISO, UN, FDA, or NSF certifications to ensure product quality and regulatory compliance.

- Lead Times and Availability: Confirm production capacity, lead times, and inventory availability—especially if you require large volumes or custom orders.

- Geographic Reach: Choose a supplier with reliable shipping options and distribution networks to your region or country.

- Customization Services: If you need branded barrels, color-coding, or specialized closures, select a manufacturer with in-house customization capabilities.

- Customer Service: Responsive support for order tracking, technical questions, and after-sales service is vital for a smooth procurement experience.

Ready to Buy Plastic Barrels?

Ready to find the best plastic barrel for your operation? Browse our list of plastic barrel manufacturers to compare products, specifications, and pricing. Whether you need food-grade, UN-certified, or custom plastic barrels, our supplier directory connects you with trusted industry leaders.

Conclusion: Why Plastic Barrels Are the Industry Standard

Plastic barrels have earned their status as the leading industrial container solution due to their durability, versatility, and cost-effectiveness. From chemical storage to food processing, agriculture, pharmaceuticals, and beyond, these containers offer unmatched performance, safety, and value. By understanding the manufacturing processes, applications, and key decision factors, buyers and procurement professionals can confidently select the right plastic barrel supplier and product for their needs.

Still have questions or need expert guidance? Contact us today for personalized recommendations or explore our knowledge base for in-depth articles on plastic barrel types, safety standards, and industry applications.

55 Gallon Drums

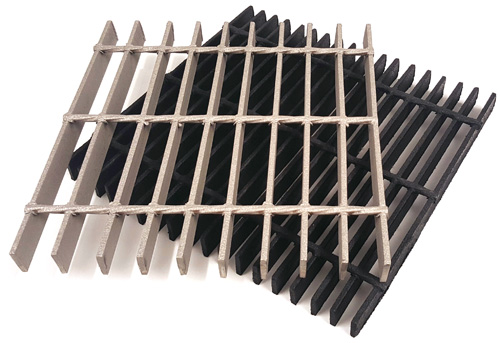

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services