Metal drums are used in many industries to store hazardous chemicals and all kinds of industrial goods. Metal drums are used for storing water, liquids, fuel, foods like grains and spices, oils, lubricants, solvents, chemicals, hazardous waste, and sand. Steel drums are the most versatile and popular among many commercial and industrial sectors; these are found in warehouses for the transportation of goods. Steel drums are cylindrical barrels specially designed to hold large quantities of liquids, semi-liquids, oils, chemicals, and food products. These are hard to wear, cost- effective, reusable, and long-lasting. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Metal Drum Manufacturers

If you’re exploring steel drums for industrial packaging, hazardous material storage, chemical transportation, or bulk logistics, understanding your options is crucial for safety, compliance, and operational efficiency. Steel drums—also known as metal drums or industrial barrels—are indispensable containers across manufacturing, chemical processing, food production, pharmaceuticals, and waste management. There are two primary types of steel drums: open-head (removable lid) and tight-head (closed-head). The open-head metal drum features a detachable lid, ideal for packaging and dispensing bulk solids, powders, viscous substances, or semi-liquids such as adhesives and gels. In contrast, the tight-head drum is sealed except for small bung openings, making it the industry standard for transporting liquids, hazardous chemicals, and volatile materials due to its leak-resistant design. Both variants can be equipped with specialized drum accessories—such as bungs, gaskets, locking rings, and safety valves—to ensure secure, spill-free handling and regulatory compliance in demanding environments. Choosing the correct type and configuration is a vital decision in supply chain management, workplace safety, and environmental protection.

Types of Steel Used in Metal Drum Manufacturing

Steel is the preferred material for manufacturing industrial drums due to its unmatched combination of strength, impact resistance, chemical compatibility, and cost-effectiveness. When selecting an industrial drum for your specific application, it’s important to evaluate the distinct properties of different steel grades and alloys. The three most widely used steel types in drum fabrication are:

Carbon Steel Drums

- Higher carbon content enhances steel’s hardness and tensile strength, making it suitable for heavy-duty industrial applications where durability is paramount.

- Carbon steel is an alloy of iron and carbon, typically containing 0.12% to 2% carbon by weight.

- Low-carbon steel exhibits excellent malleability and impact resistance, making it ideal for general-purpose storage and transport.

- High-carbon steel can be heat-treated for maximum durability and a clean, impurity-free finish, supporting long-term use under harsh conditions.

Carbon steel drums are the workhorses of the packaging sector. They are extensively used for the safe storage and transport of hazardous chemicals, industrial oils, solvents, lubricants, and waste. Their robust construction and resistance to physical damage make them indispensable in the chemical processing, oil and gas, wastewater treatment, and petrochemical industries. These drums are also commonly used for paint, adhesives, and other materials where chemical compatibility and mechanical integrity are critical. When evaluating carbon steel drum options, consider thickness, internal coatings, and UN ratings to ensure compliance with environmental and safety regulations.

Stainless Steel Drums

- Stainless steel drums provide superior resistance to corrosion, rust, and chemical attack—even in harsh, moist, or saline environments.

- A protective chromium oxide film forms on the surface, preventing oxidation and chemical degradation, which is essential for storing reactive chemicals.

- Stainless steel’s bright, hygienic finish and antibacterial properties make it ideal for sensitive, contamination-free storage.

- These drums are easy to clean, sterilize, and do not require additional painting or protective coatings, supporting GMP (Good Manufacturing Practice) protocols.

Stainless steel drums are the gold standard for sectors demanding the highest levels of purity and corrosion resistance. Food and beverage processors, pharmaceutical manufacturers, cosmetic companies, and biotechnology firms rely on stainless steel for storing edible oils, syrups, flavorings, pharmaceutical compounds, and cosmetic bases. The non-reactive surface of stainless steel maintains ingredient quality, extends shelf life, and ensures compliance with food safety and pharmaceutical regulations. Stainless steel barrels are also favored in applications where product purity, hygiene, and long-term durability are essential, such as in water treatment plants, high-purity chemical manufacturing, and laboratory research.

Cold-Rolled Steel Drums

- Cold-rolled steel drums are distinguished by their smooth, uniform finish and increased strength from the cold reduction process.

- They feature higher hardness and dent resistance compared to hot-rolled steel drums, making them ideal for rugged environments and heavy-duty logistics.

- The precise tolerances of cold-rolled steel support tight drum dimensions, facilitating reliable stacking, automated filling, and effective sealing in mass production.

Cold-rolled steel drums are favored for applications where high tensile strength, dimensional accuracy, and formability are essential—such as military logistics, mining, defense, and hazardous waste containment. The refined surface finish is well-suited for situations requiring effective sealing, branding, or consistent drum stacking in warehouses and shipping containers. Cold-rolled barrels are also popular in high-speed filling lines and export packaging, where dimensional consistency and surface quality directly impact efficiency and product safety.

Comparing Steel Drum Materials: Which One Is Right for You?

Choosing the correct steel drum material is pivotal to the safety, compliance, and efficiency of your storage or transport operation. If you need a cost-effective solution with solid performance, carbon steel drums are a versatile choice, balancing price and ruggedness. For maximum protection against corrosion or for sanitary, food-grade storage, stainless steel drums are unmatched. When dimensional accuracy, high strength, or stackability are priorities, cold-rolled steel drums are the answer. Not sure which drum material fits your needs? Explore common use cases below, or connect with trusted drum suppliers for tailored advice. Consider your industry, product sensitivity, transport requirements, and relevant compliance standards when making a decision.

How Are Steel Drums Manufactured?

The manufacturing of steel drums is a highly engineered process combining advanced material science, precision forming, and rigorous quality assurance. Whether you require UN-certified drums for hazardous materials or standard industrial containers, understanding the production process helps you evaluate product quality and compliance. The roll forming method is the industry standard, typically involving three core stages:

Forming and Shaping

Steel drums start as flat sheets of steel, which are then cut and formed into cylindrical bodies and end components. The forming process includes:

- Sheet Metal Cutting: Steel sheets are cut to precise dimensions for the drum shell, lid, and bottom plate.

- Punching and Tapping: Drum ends are punched with accurate openings for bungs, vents, and custom fittings, as required by the end user.

- Blanking: Metal blanks are shaped into drum components, with threading or holes prepared for closures, plugs, and safety accessories.

Automated roll forming and stamping lines ensure each drum meets tight tolerances, reducing waste and ensuring repeatable quality for bulk orders. Precision machinery supports high-volume production, while custom tooling enables flexibility for unique drum designs and specifications.

Welding and Assembly

Seam welding is essential for the drum’s structural integrity and leak-proof performance. Using rotating electrode wheels, the longitudinal seam of the drum body is fused under heat and pressure, creating a continuous, robust weld. This is especially critical for UN-rated steel drums designed for hazardous goods, as it prevents leaks during transport and handling. Drum ends, bungs, and reinforcement rings are then assembled to complete the container. Automated inspection systems and non-destructive testing are often used to verify weld quality and ensure each drum meets regulatory standards.

Surface Treatment: Coating, Painting, and Linings

After assembly, steel drums undergo multiple finishing steps to maximize their service life and chemical compatibility:

- Cleaning and Surface Preparation: Removal of manufacturing residues, oils, and oxides using industrial washing or abrasive blasting.

- Corrosion Protection: Application of anti-corrosion coatings such as epoxy, phenolic, or zinc-rich primers, tailored to the contents being stored.

- Painting and Branding: Exterior painting for color coding, company branding, or regulatory labeling (such as hazard identification colors).

- Specialty Internal Linings: For food, pharmaceutical, or aggressive chemical storage, specialty linings (FDA-approved, epoxy phenolic, or BPA-free) are applied to prevent product contamination or metal interaction.

After curing, each drum is tested, marked with batch codes, and inscribed with regulatory markings to ensure traceability and compliance with UN, DOT, and international packaging standards. Quality assurance includes hydrostatic leak testing, drop testing, and stack testing, ensuring that every drum shipped meets the highest industry standards for safety and performance.

What Are the Key Applications and Use Cases for Steel Drums?

Steel drums are essential across virtually every industrial sector, prized for their strength, stackability, and ability to safely contain both hazardous and non-hazardous materials. If you’re evaluating packaging for chemicals, fuels, food-grade substances, or specialty materials, metal drums offer unmatched versatility, safety, and regulatory compliance. Key applications include:

- Transport and Logistics: Shipping and storing bulk chemicals, oils, fuels, hazardous waste, and industrial liquids both domestically and internationally. Steel drums meet UN, DOT, IMDG, ADR, and IATA standards for dangerous goods packaging and shipping.

- Construction and Building Materials: On-site storage and handling of cement, resins, adhesives, sealants, and construction chemicals. Drums enable safe containment and easy dispensing of bulk materials at job sites.

- Food and Beverage Industry: Hygienic storage of edible oils, syrups, liquid sugar, flavor extracts, and food additives. Stainless steel drums are critical for preventing contamination and maintaining product integrity in commercial kitchens, breweries, and food processing plants.

- Pharmaceutical and Medical: Secure containment of pharmaceutical ingredients, medical devices, active pharmaceutical ingredients (APIs), and sensitive chemicals requiring sterile, contamination-free environments. Steel drums support GMP and regulatory compliance for medical and healthcare logistics.

- Chemical and Petrochemical: Storage of solvents, acids, caustics, lubricants, biocides, pesticides, and specialty chemicals for industrial and agricultural operations. Steel drums offer the chemical resistance and safety features required for hazardous materials.

- Waste Management: Collection, storage, and safe transport of hazardous and non-hazardous waste streams—such as oily rags, used solvents, contaminated soils, and industrial byproducts—for disposal, recycling, or incineration. Drums are engineered to contain spills and prevent environmental contamination.

- Specialized Industrial Applications: Used in mining, defense, aerospace, and heavy manufacturing for secure storage and transport of valuable, dense, or hazardous materials. Steel drums are also integral to emergency response and spill containment strategies.

- Creative and Upcycling Uses: Repurposed steel drums are popular for making industrial furniture, planters, BBQ grills, rainwater harvesting barrels, and event decor. Their structural integrity and iconic design lend themselves to both functional and decorative projects.

Looking for Specific Steel Drum Applications?

Are you searching for food-grade storage solutions? Need to meet UN requirements for hazardous waste containment? Find the right drum by exploring steel drum sizes, linings, and certifications, or request a custom quote from top manufacturers. Not sure how to select a drum for your unique product? Ask our experts: What’s the best drum for corrosive chemicals, or for hot-fill food products? How do you ensure compatibility with automated filling lines or export regulations?

Benefits of Using Steel Drums

Steel drums remain the global standard for industrial packaging for a reason. If you’re comparing steel vs. plastic or fibre drums, consider these crucial benefits:

- Unmatched Strength and Durability: Steel drums endure rough handling, stacking, and exposure to extreme temperatures, making them ideal for demanding supply chains. Their structural integrity protects valuable and hazardous contents from impact damage and punctures.

- Superior Chemical and Corrosion Resistance: With proper linings and coatings, steel drums safely store corrosive chemicals, aggressive solvents, and hazardous waste, ensuring product safety and regulatory compliance.

- Reusability and Eco-Friendly: Steel drums can be cleaned, reconditioned, and reused, supporting sustainability and reducing lifecycle costs compared to single-use containers. Many industries have established drum reconditioning and recycling programs.

- Regulatory Compliance: Designed to meet stringent global standards (UN, DOT, IMDG, IATA), steel drums enable legal and safe transport of dangerous goods worldwide and are accepted by international regulatory authorities.

- Fire Resistance: Unlike plastic drums, steel containers are fire-resistant, making them safer for flammable and combustible liquids. This feature is critical for chemical plants, refineries, and hazardous material handlers.

- Stackability and Efficient Storage: Rigid construction allows safe vertical stacking, optimizing warehouse and transport space. Drum pallets and automated handling equipment are designed with steel drum standards in mind.

- Versatile Sizing and Customization: Available in capacities from 5 to 110 gallons (20 to 420 liters), with options for open-head, tight-head, specialty linings, and custom branding. Custom drum designs can accommodate unique product requirements, such as heated drums or anti-static finishes.

- Global Availability and Compatibility: Manufactured and accepted worldwide, steel drums are compatible with standard handling equipment, pallets, and shipping systems, simplifying logistics for international supply chains.

- Ease of Recycling: Steel is among the world’s most recycled materials—scrap drums can be processed and reused, minimizing environmental impact and supporting circular economy initiatives.

Comparing Steel Drums vs. Plastic and Fibre Drums

Still evaluating your options? While plastic drums are lightweight and corrosion-resistant, they cannot match the mechanical strength, fire resistance, and regulatory compliance of steel drums. Fibre drums are economical for dry goods but lack the durability and chemical compatibility required for hazardous liquids. Read our comprehensive drum comparison guide to identify the best industrial packaging solution for your application. Need help choosing between steel, plastic, or fibre? Ask yourself: What are my product’s chemical properties? What safety regulations apply to my supply chain? How important is reusability or environmental impact?

How to Choose the Best Metal Drum Manufacturer or Supplier

Finding a reliable steel drum manufacturer or distributor is essential for quality assurance, cost control, and compliance. Here’s how to evaluate suppliers and streamline your procurement process:

- Check Supplier Credentials: Look for industry certifications (ISO 9001, UN certification) and proven track records in your sector. Choose a manufacturer with experience in your industry’s regulatory requirements.

- Explore Product Range: Assess available drum sizes, types (open-head, tight-head), specialty linings, coatings, and value-added services (such as custom branding or labeling). A diverse product portfolio indicates flexibility and expertise.

- Examine Manufacturing Capabilities: Prioritize suppliers with modern manufacturing lines, robust quality assurance programs, and in-house testing for leak-proof, UN-rated drums. Automated inspection and traceability systems are a plus.

- Request Samples and Compliance Documentation: Obtain product samples, test reports, and certification documents for peace of mind and regulatory checks. Ask about previous case studies in your application area.

- Evaluate Logistics and Lead Times: Ask about minimum order quantity (MOQ), production lead times, regional distribution networks, and international shipping options. Quick turnaround and strong logistics support can reduce downtime in your operations.

- Assess Technical Support: Strong sales and technical support teams are vital for custom orders, troubleshooting, and after-sales service. Look for suppliers who offer consultation on drum compatibility, regulatory compliance, and custom engineering.

Maximize your success by comparing multiple suppliers using our curated steel drum supplier directory. Supplier profiles highlight certifications, core competencies, and specialization by industry. Use built-in contact forms to request quotes and product information, or preview supplier websites directly. Our streamlined RFQ system lets you send requests to several manufacturers at once, ensuring competitive pricing and the best fit for your project. Need guidance on supplier selection? Ask: Does the supplier offer reconditioning services? Can they provide food-grade or hazardous material certification? What is their track record for on-time delivery?

Frequently Asked Questions About Steel Drums

- What is the standard size of a steel drum? The 55-gallon (208-liter) drum is the most common, but drums range from 5 to 110 gallons for diverse industrial applications. Consult your supplier for custom and specialty sizes.

- What certifications are required for shipping hazardous materials? Choose UN-certified steel drums rated for your material’s hazard class. These drums pass strict tests for leak, drop, and stack resistance, and are legally required for shipping dangerous goods internationally.

- Are steel drums recyclable or reusable? Absolutely. Steel drums are fully recyclable and can be reconditioned, supporting the circular economy and reducing waste. Many suppliers offer drum reconditioning and recycling programs to extend drum life and minimize costs.

- What closure types and fittings are available? Options include 2” and ¾” bungs, gaskets, locking rings, pressure-relief valves, and custom dispensing fittings, ensuring leak-proof and safe operation for your specific product and process needs.

- How do I select the right drum for my needs? Assess chemical compatibility, required certifications, drum size, closure type, and any specialty linings or coatings. Consider your industry’s regulations and handling requirements. Not sure? Ask our experts for a recommendation.

- Can I get food-grade steel drums? Yes. Stainless steel drums and certain coated carbon steel drums are certified food-grade and safe for direct contact with edible products. Always request food-grade certification and documentation from your supplier.

- What is the difference between open-head and tight-head drums? Open-head drums have removable lids, ideal for solids or thick liquids, while tight-head drums are sealed except for small bungs, best for liquids and hazardous chemicals. Your choice depends on product viscosity, filling method, and safety requirements.

- How do I ensure drum compatibility with my filling and dispensing equipment? Confirm drum dimensions, bung sizes, and thread types with your equipment specifications, or consult with your drum supplier for expert guidance. Many suppliers can provide compatibility charts and technical drawings.

- What are common mistakes to avoid when buying steel drums? Failing to verify UN certification for hazardous materials, overlooking internal drum linings for corrosive products, and not confirming compatibility with your filling/dispensing systems are frequent errors. Work closely with your supplier to avoid costly issues.

- How can I get replacement parts or drum accessories? Most steel drum suppliers offer a full range of accessories, including replacement bungs, gaskets, locking rings, liners, and dispensing valves. Ask about availability when placing your order.

Ready to Purchase Steel Drums?

Take the next step by browsing our steel drum supplier directory. Whether you require standard 55-gallon drums, specialty drums for hazardous materials, or bulk orders with custom features, our vetted network of manufacturers and distributors will help you find the right solution. Request a quote today and experience why steel drums are the world’s leading choice for safe, cost-effective, and regulatory-compliant industrial packaging. Not sure what to request? Search for: UN-rated drums for chemicals, food-grade drums for edible oils, or reconditioned drums for sustainable operations.

Still Have Questions?

Need custom drum solutions, unique linings, or global shipping? Contact our steel drum experts for personalized consulting, technical advice, and to discuss your project’s requirements. We’re committed to helping you achieve the best results for your business, no matter your industry or application. Our team can help with regulatory compliance, drum reconditioning, logistics coordination, and much more.

Explore More About Steel Drum Solutions

Want to learn more about steel drum regulations, best practices for hazardous material storage, or how to optimize your supply chain with reusable industrial packaging? Visit our Steel Drum Resource Center for in-depth guides, compliance checklists, and real-world case studies. Empower your procurement process with expert insights and up-to-date information on steel drum innovations, applications, and industry trends. Browse topics like: “How to select UN-certified drums,” “Drum reconditioning and recycling,” and “Best practices for safe drum handling and transport.”

Start Your Steel Drum Search Now

Ready to compare prices, specifications, and supplier capabilities? Use our Steel Drum Quote Tool to receive competitive offers from top manufacturers. Save time and reduce risk by sourcing directly from established, certified suppliers trusted by leading brands worldwide. Get started today: Find the best steel drum manufacturer, request custom drum specifications, and ensure your packaging meets all industry standards.

55 Gallon Drums

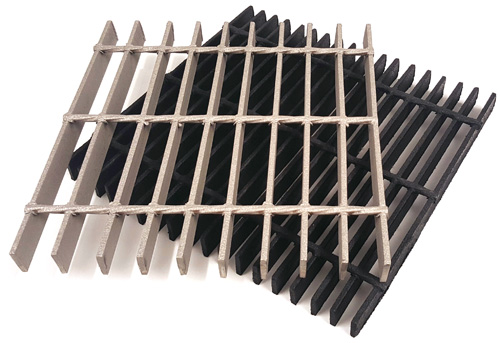

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services