As a result, industrial drum manufacturers often strengthened their drums with corrugations, called reinforcing rings, of the thickened material at each quarter of the drum to strengthen the sides and prevent denting or puncturing when rolled or turned. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

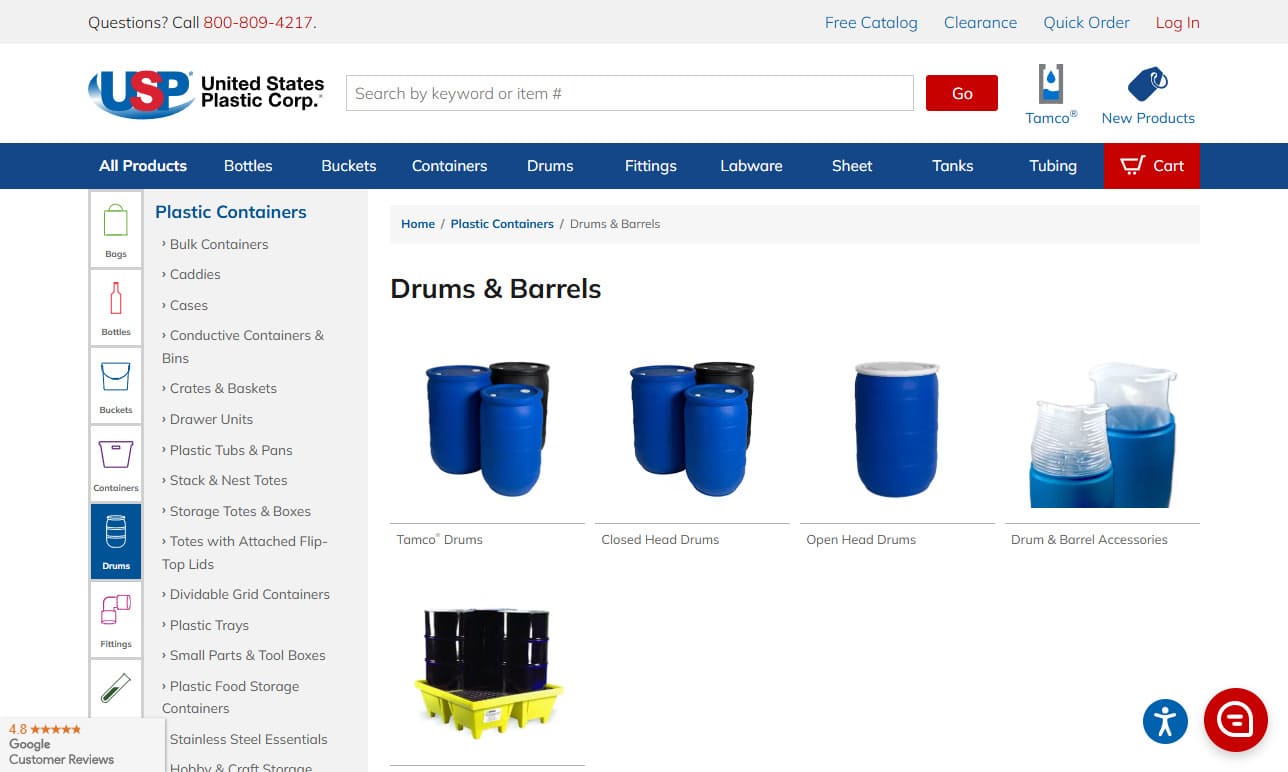

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Industrial Drum Manufacturers

Industrial Drums: Types, Applications, and Buying Guide

Industrial drums are essential containers widely used for storing and transporting liquids, solids, and semi-solids across numerous industries. When choosing the right drum for your application, understanding the differences between drum types, materials, and their specific use cases is crucial for safety, regulatory compliance, and cost-effectiveness. In this comprehensive guide, we’ll cover everything you need to know about industrial drums, including closed head drums (tight head drums), open head drums, and the main materials used in drum manufacturing: steel, plastic, and fiber. We’ll also address key considerations for selecting the right drum, frequently asked questions, and important industry standards.

Closed Head vs. Open Head Drums: What’s the Difference?

Two common ways that industrial drums are differentiated are whether they are closed head or open head drums. Understanding this distinction is fundamental when evaluating which drum best fits your material handling and shipping requirements:

- Closed Head Drums (Tight Head Drums): These have a permanent, non-removable lid with one or more small openings (bungs) for filling and dispensing. The secure seal makes them ideal for transporting and storing liquids, especially chemicals, hazardous materials, fuels, and oils that require leak-proof containment.

- Open Head Drums: Open head drums feature a fully removable lid secured with a ring or clamp. This design makes them suitable for storing and accessing solids, powders, viscous substances, and materials that require frequent opening or cleaning. The removable top also facilitates filling, emptying, and cleaning, making these drums popular for bulk storage and industrial shipping applications.

Industrial Drum Materials: Steel, Plastic, and Fiber

Industrial drums are constructed from three primary materials, each offering unique benefits and best-fit use cases. Choosing the right drum material is essential for product safety, regulatory compliance, and cost efficiency:

- Steel Drums: Known for their strength and durability, industrial steel drums are typically manufactured from stainless steel, cold-rolled steel, or carbon steel. These drums provide exceptional protection against impact and are widely used for shipping flammable chemicals, hazardous substances, solvents, and oils. Stainless steel drums are particularly valued in sanitary and anti-corrosive applications, such as food processing and pharmaceutical manufacturing, due to their FDA-approved material status and resistance to chemical corrosion.

- Plastic Drums: Plastic drums are highly versatile, lightweight, and corrosion-resistant, making them ideal for storing and transporting caustic and acidic materials, detergents, and food-grade products. Made from high-density polyethylene (HDPE), nylon, polystyrene, or PVC, plastic drums are often referred to as "blue barrels" due to their characteristic color. They excel in storing liquid and low-viscosity foods, chemicals, lubricants, and powders, offering a cost-effective, non-rusting alternative to steel.

- Fiber Drums: Constructed from dense fiberboard or heavy-duty paper, fiber drums provide a lightweight, low-cost, and eco-friendly solution for shipping solid goods, such as powdered chemicals, grains, food products, and pharmaceuticals. Fiber drums are fully incinerable and easily recyclable, making them an environmentally conscious choice for companies seeking to reduce their carbon footprint.

Typical Drum Sizes and Capacities

One of the most common drum sizes in shipping and industrial applications is the 55-gallon drum. However, industrial drums are available in a range of capacities to suit diverse needs, including 5-gallon, 15-gallon, 30-gallon, and 85-gallon drums. Drum dimensions and volume requirements should be carefully considered based on your storage and logistics needs.

- 55-Gallon Drums: The industry standard for bulk liquid and chemical storage, offering optimal balance between capacity and handling.

- Smaller Drums (5-30 Gallons): Ideal for smaller batch processing, laboratory use, or storage of specialty chemicals and additives.

- Large Overpack Drums (85 Gallons and Above): Used for spill containment, hazardous waste disposal, and transport of large-volume materials.

Are you unsure which drum size is right for your business? Contact our drum specialists for a custom recommendation based on your specific application, regulatory requirements, and logistics constraints.

Key Applications and Industry Use Cases

Industrial drums are utilized in a wide variety of industries, thanks to their adaptability, strength, and ability to safely contain a broad spectrum of materials. Common sectors and use cases include:

- Chemical Processing: Safely store and transport hazardous chemicals, solvents, and reagents in compliance with DOT and UN regulations.

- Oil & Gas: Reliable containment for petroleum products, lubricants, fuels, and drilling fluids—critical for both upstream and downstream operations.

- Food and Beverage: Sanitary storage of food ingredients, flavorings, edible oils, syrups, and bulk grains. FDA-compliant drums are essential for ensuring food safety.

- Pharmaceuticals: Secure storage and shipping of active pharmaceutical ingredients (APIs), excipients, and finished drug products under GMP-compliant conditions.

- Construction: On-site containment of adhesives, paints, coatings, and construction materials with robust, reusable drums.

- Water & Wastewater Treatment: Handling of water treatment chemicals, sludge, and waste materials in corrosion-resistant drum containers.

- Agriculture: Bulk storage and transport of fertilizers, pesticides, animal feed, and crop protection products.

- Waste Management: Collection and secure disposal of hazardous and non-hazardous industrial waste, ensuring compliance with environmental regulations.

Wondering how industrial drums are used in your specific industry? Explore our industry solutions or request a use case consultation to discover the best drum options for your operational needs.

Buyer’s Guide: How to Choose the Right Industrial Drum

Choosing the right industrial drum is a critical decision that can impact safety, regulatory compliance, operational efficiency, and total cost of ownership. Here are the key factors to consider when evaluating drum suppliers and selecting the best drum for your needs:

- Material Compatibility: Ensure the drum material is compatible with the product being stored or transported. For instance, steel drums are best for flammable or corrosive chemicals, while plastic drums excel with acids and food products. Fiber drums are suitable for dry bulk goods.

- Regulatory Compliance: Verify that the drum meets relevant standards and certifications, such as UN/DOT ratings for hazardous materials, FDA approval for food contact, or GMP requirements for pharmaceuticals.

- Capacity & Dimensions: Select the appropriate drum size and shape for your batch volume, storage space, and handling equipment.

- Head Type: Decide between closed head (for liquids and hazardous materials) and open head (for solids, powders, and easy access) based on your intended application.

- Closure Mechanism: Evaluate bung types, gaskets, locking rings, and sealing methods to ensure a secure, leak-proof closure suitable for your material.

- Handling & Logistics: Assess drum weight, stackability, palletizability, and compatibility with forklifts or drum handling equipment for efficient transport and storage.

- Environmental Impact: Consider the drum’s recyclability, reusability, and end-of-life disposal options to align with your company’s sustainability goals.

- Cost & Supplier Reputation: Balance upfront costs with long-term value, including durability, reusability, and maintenance. Choose suppliers with proven industry expertise and reliable delivery.

Need help choosing the best industrial drum for your operation? Ask our experts for a personalized recommendation or request a sample drum to test in your facility.

Benefits of Using Industrial Drums

Industrial drums offer numerous advantages for companies handling bulk materials. Here are some of the top benefits that drive businesses to choose drum packaging solutions:

- Safe Containment: Engineered to prevent leaks, spills, and contamination, drums provide superior protection for hazardous, reactive, or sensitive materials.

- Cost-Effective Bulk Storage: Drums enable efficient storage and shipment of large volumes, reducing handling costs and minimizing packaging waste compared to smaller containers.

- Regulatory Compliance: Many industrial drums are UN/DOT certified, ensuring compliance with transportation and environmental safety standards.

- Versatility: Available in a wide range of materials, sizes, and closure types to accommodate virtually any industry or application.

- Reusability & Recyclability: Steel and plastic drums can be cleaned and reused multiple times, while fiber drums are easily recycled or incinerated, supporting circular economy initiatives.

- Stackability & Space Efficiency: Industrial drums are designed for safe stacking and efficient use of warehouse or transport space.

Want to learn more about the benefits of industrial drums for your specific material or process? Contact us for a detailed product comparison or download our industrial drum selection guide.

Frequently Asked Questions About Industrial Drums

What types of industrial drums are best for hazardous materials?

For hazardous materials, UN-rated steel drums and UN-certified plastic drums are recommended. These drums meet stringent international shipping and storage standards, ensuring safe containment and transport of dangerous goods. Always verify UN markings and consult your safety officer before selecting a drum for hazardous material handling.

How should I clean and maintain industrial drums?

Proper maintenance extends drum life and ensures safety. Clean drums with compatible cleaning agents after each use, inspect for corrosion or damage, and follow supplier guidelines for reconditioning or recycling. Specialized drum cleaning and reconditioning services are available from most industrial drum suppliers.

Are used industrial drums safe for reuse?

Used drums can be reused if properly cleaned, inspected, and certified for their intended application. Ensure drums are free from residue and not compromised structurally. For critical or regulated applications (food, pharma, hazardous materials), always use new or reconditioned drums with appropriate certification.

What is the difference between a barrel and a drum?

While the terms are sometimes used interchangeably, "drum" typically refers to standardized industrial containers (like 55-gallon drums), whereas "barrel" is a broader term and may refer to smaller or specialized containers, such as wine or whiskey barrels. In industrial settings, "drum" is the preferred term for large, cylindrical bulk containers.

How do I dispose of or recycle industrial drums?

Drum disposal and recycling depend on drum material and previous contents. Steel and plastic drums can often be reconditioned or recycled through certified drum recyclers. Fiber drums are usually incinerated or recycled as cardboard. Always follow local regulations for hazardous material residue and seek guidance from your drum supplier or local waste management authorities.

Industrial Drum Standards and Certifications

When selecting industrial drums for your business, it is essential to consider regulatory compliance and industry certifications. Key standards include:

- UN/DOT Ratings: Required for drums used in the transport of hazardous materials, ensuring leak-proof performance and impact resistance.

- FDA Compliance: Critical for food, beverage, and pharmaceutical applications to guarantee safety and hygiene.

- GMP (Good Manufacturing Practice): Applies to pharmaceutical and food-grade drums for consistent quality and traceability.

Looking for certified drums for regulated applications? Browse our UN/DOT and FDA-approved drum selection or request compliance documentation from our experts.

Choosing the Best Supplier for Industrial Drums

Sourcing industrial drums from a reputable supplier is vital for product quality, safety, and supply continuity. When evaluating suppliers, consider:

- Product range and customization capabilities (custom drum sizes, colors, materials)

- Certifications and compliance with industry standards (UN, FDA, GMP)

- Lead times, stock availability, and delivery logistics

- Technical support, customer service, and after-sales assistance

- Reconditioning, recycling, and drum return programs

Ready to request a quote or compare drum suppliers? Get in touch with our sales team for competitive pricing, samples, or technical datasheets.

Conclusion: Selecting the Right Industrial Drum for Your Business

Whether you need steel drums for hazardous chemicals, plastic drums for food-grade liquids, or fiber drums for dry goods, understanding the types, applications, and benefits of industrial drums is key to optimizing your material handling strategy. Consider your product’s compatibility, regulatory requirements, and operational needs when selecting a drum, and always buy from a trusted, certified supplier.

Still have questions about industrial drum solutions? Explore our in-depth resources, check our product catalog, or chat with a drum expert to find the best packaging for your operation.

55 Gallon Drums

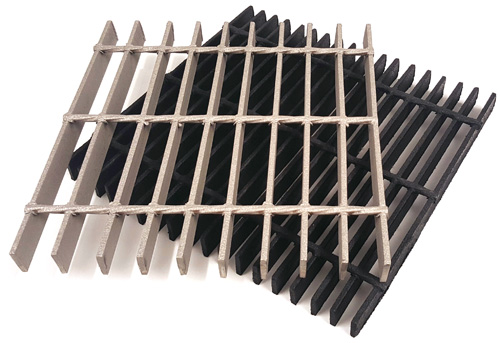

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services