Fulfilling a wide range of packaging requirements in industries such as chemical, pharmaceutical, glue, paint and food processing, cardboard drums are a safe and sanitary method for shipping even small parts. Depending on the intended application and contents of the fiber drums, the drums are made in different amounts of heavy paperboard layers, or fiber materials. They are very sturdy and can hold a great deal of weight in either liquid or solid form. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

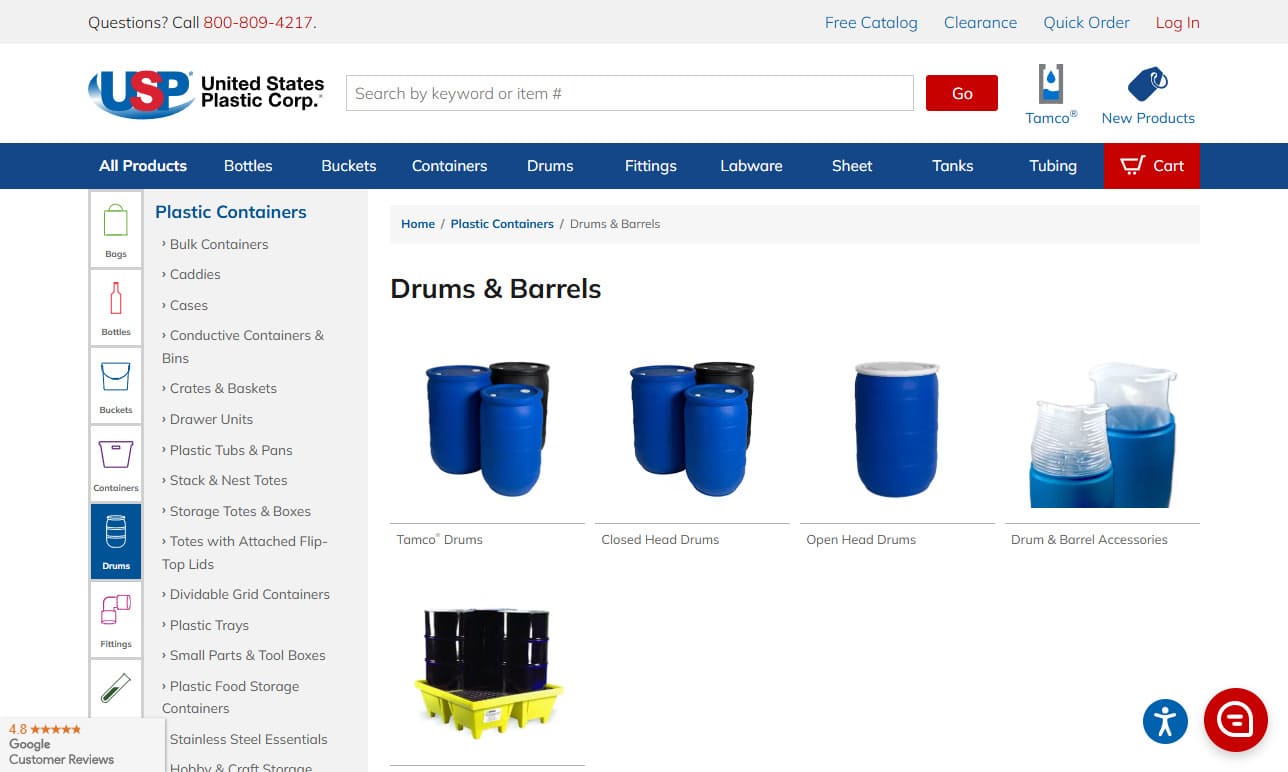

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Fiber Drum Manufacturers

Fiber Drums for Industrial Shipping and Storage: Versatile, Eco-Friendly Solutions

When selecting the best industrial packaging solutions for bulk goods, hazardous substances, or sensitive materials, businesses often evaluate the merits of fiber drums for their cost efficiency, flexibility, and sustainability. Also known as paper drums or cardboard drums, fiber drums have become a preferred choice for a wide range of industries demanding secure, reliable, and environmentally friendly packaging methods. Whether you’re searching for UN-rated fiber drums, custom fiber drum sizes, or fiber drums with liners for specialty applications, understanding their unique features and benefits can help you make an informed purchasing decision and optimize your supply chain efficiency.

What Are Fiber Drums? Defining a Versatile Packaging Solution

Fiber drums are cylindrical containers constructed primarily from multiple layers of high-strength paperboard or fiberboard. Their innovative design provides a lightweight yet robust solution for the storage and transport of solids, semi-solids, powders, granules, and even certain liquids. Fiber drums are widely used in industries such as pharmaceuticals, chemicals, food processing, agriculture, hazardous materials handling, and more.

- Available in a variety of diameters and heights for adaptable storage and shipping solutions

- Manufactured to accommodate a range of weight capacities and product specifications—from lightweight powders to heavy bulk materials

- Can be fitted with plastic drum liners or barrier bags for enhanced protection against moisture and contaminants

- Offer options for custom linings, coatings, and closure types based on specific application needs and regulatory requirements

- Support a range of packaging needs, including stackability, ease of handling, and tamper-evidence

Heavy-Duty Reinforcements: Steel Rings and Metal Covers

For applications involving heavy, dense, or high-value materials, fiber drums can be upgraded with steel rings that reinforce both the top and bottom, significantly increasing the drum’s structural integrity and stacking strength. Additionally, a metal cover can replace the standard fiberboard lid to further decrease the risk of product contamination and enhance tamper resistance. These reinforcements make fiber drums suitable for the secure transport and storage of both hazardous and non-hazardous materials, including regulated chemicals and industrial powders.

Wondering which drum is right for your application? Compare fiber drums to metal drums and plastic drums to determine the best fit for your business’s needs, considering factors such as chemical compatibility, impact resistance, temperature tolerance, and regulatory compliance. Each drum material offers unique advantages for different use cases.

Compliance with International Shipping Standards

Both hazardous and non-hazardous materials can be safely transported using fiber drums because, like steel drums and plastic drums, fiber drums are required to meet stringent international shipping standards such as UN certification and DOT approval. These standards ensure the drums are of high quality and capable of withstanding the rigors of global logistics, including rough handling, stacking, and environmental exposure. Look for UN-certified fiber drums and DOT-approved fiber drums if you need to ship regulated or hazardous materials across borders or via multiple modes of transport.

Why Is Compliance Important?

Using certified fiber drums ensures your shipments meet legal and safety requirements, minimize risk during transit, and avoid costly fines or delays. If you’re not sure whether you need a UN-rated drum for your application, consult with a packaging expert or your logistics provider.

Key Benefits of Fiber Drums

Fiber drums deliver a combination of performance, sustainability, and cost-effectiveness that is hard to match. Here are some of the main advantages:

- Cost Savings: Fiber drums are generally less expensive than stainless steel and plastic alternatives, helping to reduce your overall packaging expenses, especially for large volume shipments.

- Lightweight Construction: The paperboard construction makes fiber drums significantly lighter than metal or plastic drums, lowering shipping costs and making manual handling easier. This also reduces workplace injuries and improves ergonomics.

- Recyclable & Eco-Friendly: Fiber drums are made from renewable resources and can be recycled after use. They support corporate sustainability goals, help reduce landfill waste, and appeal to environmentally conscious customers. Many models are made with recycled content, further decreasing environmental impact.

- Durability: Despite their lighter weight, fiber drums are engineered for strength and can withstand rugged transportation and storage conditions. Their resilience is proven through rigorous compression, drop, and vibration testing by leading manufacturers.

- Corrosion Resistance: Unlike steel drums, fiberboard does not corrode, making fiber drums ideal for storing materials over long periods without risk of contamination from rust or oxidation, especially in humid or coastal environments.

- Customization: Fiber drums can be manufactured with a wide array of diameters, heights, and weight capacities. They can be tailored to meet specific application requirements, including custom printing and labeling for branding, tracking, or regulatory purposes.

- Product Protection: With the option for specialized liners, barrier coatings, and reinforced closures, fiber drums provide excellent protection against moisture, contaminants, UV exposure, and physical damage during transit. This ensures your product arrives in optimal condition.

- Easy Disposal and Reuse: Many fiber drums can be reused multiple times, and at end-of-life, they are easy to break down and recycle compared to other industrial containers.

Common Applications: Where Are Fiber Drums Used?

Fiber drums are remarkably versatile and are used across a diverse array of industries and applications. Do you need packaging for bulk powders, granules, pharmaceuticals, or food ingredients? Searching for a solution for hazardous waste, agricultural products, or specialty chemicals? Fiber drums offer a flexible, cost-effective answer that meets a broad spectrum of packaging needs.

- Pharmaceuticals: Store and transport bulk active ingredients, excipients, and finished products in sterile, contamination-free conditions. Fiber drums are widely used for API packaging, pharmaceutical intermediates, and clinical trial supply logistics.

- Chemical Manufacturing: Package powders, resins, adhesives, and specialty chemicals with options for anti-static or moisture-resistant liners. Fiber drums are ideal for both hazardous and non-hazardous chemicals due to their compliance with international safety standards.

- Food and Beverage: Maintain food safety and freshness for ingredients like grains, spices, flavorings, and sweeteners. Many food-grade fiber drums are FDA-compliant and offer odor and contamination protection.

- Agriculture: Store and ship seeds, animal feed, fertilizers, and agricultural chemicals with ease. The lightweight design makes them easy to transport on farms and in greenhouses.

- Hazardous Waste Disposal: Safely collect and transport hazardous and non-hazardous waste, including contaminated solids, absorbents, and cleanup materials. UN-rated fiber drums are specifically engineered for waste management and remediation projects.

- Construction and Industrial: Contain construction materials, adhesives, and industrial powders; fiber drums are easy to stack and move on worksites. They are also used for temporary storage of debris and recyclable materials.

- Cosmetics and Personal Care: Package bulk powders, creams, oils, and raw ingredients for further processing or distribution. The clean, inert interior protects sensitive products from contamination.

- Textiles & Dyes: Transport colorants, textile chemicals, and bulk fibers safely and efficiently—fiber drums minimize dust and spillage during handling.

Looking for a solution for your industry?

Find the right fiber drum for your unique application by contacting our experts or browsing our full range of industrial packaging products.

Comparing Fiber Drums to Steel and Plastic Drums

When evaluating fiber drums vs. steel drums or fiber drums vs. plastic drums, it’s important to consider your specific industry requirements, product characteristics, and logistical needs. Here are critical decision factors to help you choose the best packaging drum:

- Weight: Fiber drums are the lightest option, reducing logistic costs and physical strain during handling. Lighter packaging also increases payload efficiency for bulk shipments.

- Cost: Generally, fiber drums offer the lowest price point, making them the preferred choice for cost-sensitive applications or one-way shipments. Steel drums are at the high end of the spectrum, and plastic drums fall in between.

- Durability: While steel drums provide maximum impact resistance and chemical compatibility, fiber drums are highly durable for most non-liquid and dry goods applications. Reinforced fiber drums can withstand stacking and rough handling in distribution centers.

- Environmental Impact: Fiber drums are biodegradable and recyclable, appealing to companies prioritizing sustainable packaging solutions. Steel and plastic drums, while reusable, have a higher carbon footprint in manufacturing and disposal.

- Regulatory Compliance: All drum types can be UN-rated for hazardous goods, but fiber drums also offer unique customization and labeling for compliance.

- Corrosion Resistance: Unlike steel, fiberboard will not rust or corrode, making it suitable for long-term storage of moisture-sensitive materials. Plastic drums also resist corrosion but may not offer the same eco-friendly disposal options.

- Customization: Fiber drums are easily tailored to unique dimensions, branding, and product protection needs, unlike rigid steel or molded plastic drums.

Still weighing your options? Ask yourself:

- What type of material am I shipping or storing, and what regulatory requirements must I meet for packaging?

- Is product weight and shipping cost a major concern for my business?

- Do I need recyclable or eco-friendly packaging solutions to meet corporate sustainability targets?

- How important is corrosion resistance or product protection during transit and storage?

- Will my application require custom sizes, liners, coatings, or closures to ensure product safety?

- How do my packaging needs evolve with changing product lines or supply chain demands?

For a more detailed comparison, visit our guides on metal drums and plastic drums, or reach out for personalized advice.

Types of Fiber Drums: Customization and Options

Fiber drums can be engineered to meet a wide variety of requirements, making them suitable for nearly every industrial packaging application. Explore the most common types and customization options below:

- Open-Head Fiber Drums: Feature removable covers for easy filling and dispensing of materials. These are ideal for dry goods, powders, bulk solids, and applications requiring frequent access to contents.

- Closed-Head Fiber Drums: Have non-removable tops with smaller openings, suitable for liquids or semi-solids that require extra containment and spill prevention.

- UN-Rated Fiber Drums: Tested and certified for the transport of hazardous materials, meeting DOT and international shipping standards. These are critical for compliance in regulated industries.

- Fiber Drums with Liners: Offer added protection against moisture, chemicals, or cross-contamination. Liners are available in materials such as polyethylene, polypropylene, foil, or specialty barrier coatings, depending on product compatibility requirements.

- Reinforced Fiber Drums: Incorporate steel rings or metal covers for heavy-duty or high-stacking applications, increasing safety during transport and storage.

- Custom Printed Fiber Drums: Can be branded with company logos, product information, tracking barcodes, or regulatory markings for enhanced identification and traceability.

Liners, Coatings, and Closures: Enhancing Fiber Drum Performance

Many paper drums, especially those used for the storage or transportation of liquid products or sensitive materials, can be lined with a variety of coatings or insoluble materials such as polyethylene, silicone, polyester, or even aluminum foil. These drum liners create a protective barrier, enhancing chemical compatibility, improving moisture resistance, and helping to prevent product contamination or vapor transmission. In addition to heavy-duty steel lids, closures may also be made from plastic, wood, or fiber, ensuring the opening is securely sealed for safe storage and transit.

Consider which liner or closure best suits your application. For example, polyethylene liners are ideal for moisture-sensitive powders, while aluminum or foil linings offer enhanced protection for volatile chemicals. Ask: What properties should my fiber drum liner have? If you’re uncertain about chemical compatibility, regulatory requirements, or barrier performance, consult with your drum supplier to match your requirements with the right liner and closure options. Ask about anti-static liners, food-grade coatings, and tamper-evident closures for your specific use case.

Industry-Specific Applications: Fiber Drums in Action

Looking to see how fiber drums are used in your industry? Here are some typical industry applications and benefits:

- Pharmaceutical and Biotech: Fiber drums offer contamination-free storage, comply with strict regulatory standards, and support global clinical trial logistics. They are often used to transport bulk pharmaceutical ingredients and intermediates.

- Food Ingredients: Many food-grade fiber drums are FDA-approved and provide barrier protection for sensitive ingredients. They’re commonly used for spices, sweeteners, dried fruits, grains, and other bulk food commodities.

- Chemical Processing: Liners and coatings ensure compatibility with a wide range of chemicals, including powders, resins, adhesives, and specialty reagents.

- Agriculture: Fiber drums provide weather-resistant packaging for seeds, fertilizers, and animal feed, helping reduce waste and spoilage in storage or transit.

- Hazardous Waste Management: UN-rated fiber drums are used for the containment and disposal of regulated and non-regulated waste streams, including absorbents, lab debris, and contaminated soils.

- Cosmetics Manufacturing: These drums are chosen for bulk raw materials and intermediate products due to their cleanliness, ease of handling, and compatibility with a wide range of formulations.

- Paints and Coatings: Fiber drums are compatible with dry pigments, powders, and some semi-solid or paste-like formulations, offering a dust-free, contamination-resistant storage solution.

- Recycling & Waste Processing: Fiber drums are frequently used for the collection and transport of recyclables, e-waste, and process byproducts due to their cost-effectiveness and recyclability.

How to Select the Right Fiber Drum: Buying Guide & Decision Factors

When purchasing fiber drums, consider the following key decision factors to ensure you select the best drum for your needs and maximize return on investment:

- Product Type: Are you packaging dry goods, powders, liquids, or hazardous materials? Each application may require different liners, coatings, or closure types to ensure product safety and compliance.

- Drum Size and Weight Capacity: Identify your volume requirements and stacking needs. Fiber drums are available in sizes from 10 to 75 gallons or more, and custom options are widely available for unique storage or shipping configurations.

- Regulatory Compliance: Verify if your application requires UN certification or DOT approval for hazardous shipments. Always use certified drums for regulated products.

- Liner and Coating Requirements: Determine if you need chemical, moisture, or vapor resistance for your product. Ask about specialty liners for food, pharma, or chemical compatibility.

- Closure Type: Choose from steel, plastic, wood, or fiber lids and rings for the right level of security and ease of access. Consider tamper-evident and resealable closures for added protection.

- Environmental Considerations: If sustainability is a priority, confirm the drums are made from recycled materials, are recyclable after use, and meet your company’s green packaging goals.

- Customization Needs: Do you require branded printing, labeling, color-coding, or special sizing for your application? Custom drums can improve supply chain efficiency and product traceability.

- Supplier Selection: Partner with a reputable manufacturer or distributor with experience in your industry and the ability to provide technical guidance, regulatory support, and timely delivery.

- Budget and Total Cost of Ownership: Consider not just the purchase price but also shipping, handling, reuse, and disposal costs to optimize your packaging spend.

Frequently Asked Questions About Fiber Drums

What sizes do fiber drums come in?

Fiber drums are available in a wide range of sizes, typically from 10 gallons to 75 gallons, but custom diameters, heights, and capacities can be manufactured to meet specific requirements for unique products or supply chain needs.

Are fiber drums suitable for hazardous materials?

Yes, UN-rated fiber drums are designed, tested, and certified for the transport of hazardous materials and comply with DOT and international regulations. Always confirm certification when shipping regulated substances.

Can fiber drums be recycled?

Most fiber drums are made from recyclable paperboard and can be recycled after use. Remove any liners or coatings before recycling as required by local guidelines. Using recyclable drums can help you meet your sustainability and waste reduction goals.

What types of closures are available?

Fiber drums can be fitted with steel, plastic, wood, or fiberboard lids and locking rings, depending on your application and security needs. Ask your supplier about custom closure options for tamper-evidence or easy re-sealing.

Are fiber drums food safe?

Many fiber drums are manufactured to FDA standards for food contact and can be safely used for food ingredients, additives, and flavorings. Always request documentation for food-grade certification if required.

Can I get custom-printed fiber drums?

Yes, many manufacturers offer custom printing and labeling for branding, regulatory compliance, or product identification, including barcodes, QR codes, and handling instructions.

How do I choose the right liner or coating?

The best liner or coating depends on your product’s chemical compatibility, moisture sensitivity, and regulatory requirements. Consult with your supplier to select liners made from polyethylene, foil, or other specialty materials to optimize product protection.

How are fiber drums shipped and stored?

Fiber drums are easy to palletize and stack, optimizing warehouse space and shipping container utilization. Their lighter weight reduces freight costs compared to steel drums.

Why Choose Fiber Drums for Your Packaging Needs?

Fiber drums offer a unique combination of lightweight construction, durability, cost savings, and environmental sustainability. Whether you are moving bulk powders, food ingredients, hazardous materials, or specialty chemicals, fiber drums can be tailored to your exact requirements and help companies achieve their packaging, safety, and sustainability goals. Their customizable nature, wide array of sizes and liners, and compliance with international regulations make them the preferred choice for businesses seeking reliable, eco-friendly packaging.

Ready to get started? Contact our team for expert guidance on fiber drum selection, customization options, and current pricing. Or request a quote today and discover how fiber drums can streamline your supply chain, reduce costs, and support your sustainability initiatives. If you’re comparing drum types, explore our full range of industrial drum solutions to evaluate fiber, steel, and plastic options for every packaging application.

Explore More:

- Learn about metal drum advantages for hazardous goods

- Research plastic drums for chemical and liquid applications

- Ask an expert about fiber drum customization

Have more questions about fiber drums, regulatory compliance, or industrial packaging? Contact us now for detailed answers, technical data, and personalized recommendations.

55 Gallon Drums

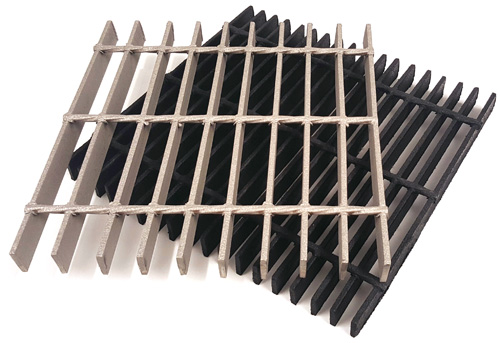

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services