More 55 Gallon Drum Companies

Drums vs. Barrels: Understanding Industry Terminology

The terms drum and barrel are frequently used interchangeably across storage and shipping sectors, as both refer to cylindrical containers designed for the safe transport and storage of liquids, powders, chemicals, and other bulk materials. Typically made from metal, fiberglass, plastic, or fiber, these containers are available in a variety of standard sizes, with the 55-gallon drum emerging as a global industry benchmark for bulk storage.

However, there are critical distinctions worth noting for buyers and industry professionals:

- Petroleum Sector: The term barrel is a precise unit in oil and gas, referring specifically to a 42-gallon oil barrel. This size is unique to petroleum and not commonly used in other markets.

- Beverage & Distilling: Traditionally, wooden barrels were utilized for aging beverages such as wine, beer, and whiskey. In modern practice, especially for transport and fermentation, sanitary stainless steel drums or food-grade plastic drums have largely replaced wood, ensuring sterility and regulatory compliance.

Despite these differences, the terms often overlap in usage due to historical precedent and industry jargon. In most contexts outside these exceptions, drums and barrels fulfill similar roles in logistics, storage, and processing operations.

Looking for a specific drum or barrel type? Jump to our in-depth guide on drum types and applications.

55-Gallon Drum Applications: Versatile Industrial & Commercial Uses

55-gallon drums have become indispensable for a wide range of industries thanks to their capacity, durability, and adaptability. Their primary use is for the safe storage and shipping of liquids, chemicals, powders, and hazardous materials, meeting rigorous international trade standards. However, their utility extends far beyond these core applications.

- Industrial & Manufacturing: Used for raw materials, lubricants, solvents, and finished goods.

- Chemical Processing: Essential for containment of acids, bases, cleaning agents, and industrial chemicals.

- Food & Beverage: Food-grade drums store syrups, oils, concentrates, and ingredients under FDA and USDA standards.

- Pharmaceuticals: Used for sterile transport of active ingredients and intermediates.

- Agriculture: Store fertilizers, pesticides, animal feed, and crop treatments safely and efficiently.

- Water Storage & Rainwater Harvesting: Plastic drums are commonly repurposed for rain barrels and emergency water storage, supporting sustainability initiatives.

- Waste Management: Hazardous waste drums ensure safe collection and transportation of regulated waste streams.

- Construction & Environmental Remediation: Used for containment of contaminated soils, debris, and site runoff.

- Creative Repurposing: Reconditioned 55-gallon drums find new life as trash bins, composters, dock floats, borders, and even furniture or barbecue smokers.

Did you know? Drums are also produced in 20, 30, and 40-gallon sizes to accommodate smaller-scale storage needs or unique process requirements. This flexibility allows industries to select the most cost-effective and operationally efficient solution.

Need help selecting the right drum for your operation? Explore our buyer’s checklist for key decision factors and supplier evaluation tips.

The History of 55-Gallon Drums: Evolution of Bulk Storage

The use of barrels and drums for storage and shipment stretches back to the Middle Ages, when wooden barrels were primarily employed for aging and transporting beer and wine. By the 1700s, these robust wooden containers became the vessel of choice for English colonists involved in import and export trade, especially for foodstuffs and spirits.

The 1800s saw the American whiskey boom, where wooden barrels became synonymous with quality aging and transportation of spirits. However, technological innovation and the demands of the burgeoning oil industry soon prompted a shift in materials and design.

In the early 20th century, the introduction of the 55-gallon steel drum revolutionized bulk liquid transport. Notably, in 1905, an employee of Nellie Bly’s Iron Clad Manufacturing Company in New York secured two patents for the modern steel drum, addressing common issues like leakiness and awkward handling associated with earlier metal designs.

Steel drums rose to prominence during World Wars I and II, serving critical roles in shipping sulfuric acid, aviation fuel, and other strategic materials. Their ruggedness and stackability made them indispensable for military logistics. Post-war, steel drums were widely adopted for gasoline and food storage, though challenges such as rust and contamination led to the development of alternative materials.

Fiber drums emerged as a lightweight, rust-resistant, and disposable alternative, particularly suited for food storage. The next innovation was the introduction of HDPE (high-density polyethylene) plastic drums in the 1960s. HDPE’s chemical resistance and cost-effectiveness made it ideal for food, pharmaceutical, and chemical sectors, establishing new FDA standards for food-grade bulk storage containers.

Today, 55-gallon drums are manufactured in a variety of materials—including steel, fiber, and a wide selection of plastics—to meet the specific needs of every industry. Sustainability and recyclability are now major focus areas, with manufacturers striving to reduce environmental impact through improved design and material sourcing.

Curious about the environmental impact of drum materials? Read about recyclability and green practices in drum manufacturing.

Drum Design & Manufacturing: Processes, Materials, and Customization

Production Process

The manufacturing process for 55-gallon drums varies by material, each optimized for durability, leak prevention, and regulatory compliance:

- Metal Drums: Constructed via roll forming and welding, followed by galvanizing or coating for corrosion resistance. Corrugated reinforcing rings are incorporated to enhance structural integrity.

- Plastic Drums: Produced using blow molding, creating seamless, high-strength vessels ideal for chemicals, food, and water storage. UV-stabilized resins can be used for outdoor or harsh environments.

- Fiber Drums: Assembled from dense paperboard or fiberboard, often with moisture-resistant liners, making them lightweight yet strong for dry goods or semi-solids.

Automated production lines feature advanced equipment such as body makers, disc cutting machines, lid and ring fixing machines, and leak testers to ensure product consistency and safety.

Materials

Material selection is critical for matching drum performance to application:

- Steel: Stainless steel, carbon steel, and cold-rolled steel are popular for high-strength, anti-corrosive, or sanitary needs. Ideal for hazardous chemicals, fuels, and food-grade applications requiring sterility.

- Plastics: HDPE is the industry standard due to its chemical inertness, impact resistance, and FDA compliance. Other options include polyvinyl chloride (PVC), polystyrene, and nylon, each offering specific advantages for certain chemicals or temperature extremes.

- Fiberboard: Used for dry goods, powders, and cost-sensitive shipments. Easily recycled and often favored for one-way or export shipments.

Considerations and Customization

While most 55-gallon drums adhere to standardized dimensions and specifications, many manufacturers offer customization to address unique operational needs:

- Custom bung hole placement or additional openings

- Specialized coatings or linings for chemical compatibility

- Color-coding, painting, or custom labeling for identification and branding

- Embossed or stamped company logos

- Stackability enhancements or reinforced designs for heavy loads

Have specific customization needs? Learn how to communicate requirements with drum manufacturers.

Key Features of 55-Gallon Drums

While steel, fiber, and plastic drums share many core functions, their design features and access methods vary to suit different contents, environments, and regulatory standards:

- Closed Top (Tight Head) Drums: Feature a permanently sealed lid with one or more bung holes for filling and dispensing. Ideal for liquids, oils, and hazardous chemicals where tamper resistance and spill prevention are critical.

- Open Top (Open Head) Drums: Have a removable cover secured with a locking ring, allowing for easy filling, cleaning, or removal of solid or viscous contents. Common in food processing, waste management, and bulk powders.

- Reinforced Corrugations: Corrugated rings at key points provide extra strength to withstand impact, stacking, and rough handling during shipping or storage.

- Stackable Design: Drums are engineered for safe vertical stacking, maximizing warehouse efficiency and reducing floor space requirements.

Drums can be moved using forklifts, drum dollies, or by rolling them on their reinforced sides—key considerations for warehouse and logistics operations.

Which drum type is right for your application? Review our breakdown of drum types, materials, and industry uses below.

Types of 55-Gallon Drums and Their Applications

All 55-gallon drums fall under either the closed head (tight head) or open head category, with a wide variety of specialized designs available for specific applications. Here’s a guide to the most common types and their typical industry uses:

- Water Barrels: Purpose-built for safe water storage, rainwater harvesting, or emergency preparedness. Most commonly made from UV-resistant HDPE plastic to prevent algae growth and withstand outdoor conditions. Industries: agriculture, disaster relief, residential, and green building.

- Hazardous Waste Containers: Designed for the secure containment and transportation of regulated chemical and industrial waste. Available in steel or high-density plastic, these drums meet rigorous EPA and DOT (Department of Transportation) standards for hazardous materials, including gasoline, solvents, acids, and medical waste.

- Used & Reconditioned Drums: Sustainably refurbished steel, plastic, or fiber drums offer a cost-effective and eco-friendly alternative for non-food-grade storage. The reconditioning process involves thorough cleaning, inspection, and certification, making them suitable for many industrial and agricultural purposes.

- 30-Gallon Steel Drums: A compact alternative for smaller batch processing, specialty chemicals, or food ingredients. Note: Steel is susceptible to rust, so plastic drums are recommended for long-term outdoor use or contact with moisture-sensitive materials.

- Steel Drums: The gold standard for flammable, corrosive, or high-value chemicals and fuels. Stainless steel variants are preferred for pharmaceuticals, food processing, and laboratory environments due to their sanitary, corrosion-resistant properties.

- Plastic Drums: Lightweight, shatter-resistant, and impervious to rust and many chemicals. Often referred to as “blue barrels,” these are popular for both industrial chemicals and food products. Their inertness makes them safe for potable water and sensitive ingredients.

- Fiber Drums: The preferred choice for dry, solid, or semi-solid contents, such as powders, grains, or frozen foods. Easily recycled, stackable, and often supplied with moisture-barrier liners for added protection.

Searching for a specialized drum type? Browse our directory of leading 55-gallon drum manufacturers and suppliers.

Advantages of 55-Gallon Drums: Why Choose This Storage Solution?

55-gallon drums offer exceptional value, flexibility, and sustainability for businesses across nearly every sector. Here’s why they remain a top choice for industrial and commercial storage:

- Cost-Effectiveness: Drums are mass-produced and widely available, keeping per-unit costs low for bulk purchases.

- Durability: Designed to withstand rough handling, stacking, and extreme temperatures, especially steel and HDPE plastic options.

- Environmental Sustainability: Most drums are recyclable or reusable. Reconditioned drums extend the product lifecycle, and many plastic and fiber drums are made from recycled materials.

- Versatility: Suitable for a wide variety of contents across industrial, agricultural, food, and commercial applications.

- Stackability and Space Efficiency: Engineered for safe, vertical stacking, which optimizes warehouse storage and reduces operational costs.

- Repurposing Potential: Used drums can be converted into rain barrels, composters, flotation devices, or even creative furniture, supporting zero-waste initiatives.

- Transportability: Designed for easy movement by pallet jack, forklift, or rolling, improving workplace efficiency and reducing manual labor costs.

Want to maximize value from your drum purchases? Read our tips for sourcing, reconditioning, and reusing 55-gallon drums.

Essential Accessories for 55-Gallon Drums

To further enhance the utility and safety of 55-gallon drums, a variety of accessories and equipment are available:

- Drum Pumps: Pneumatic or manual pumps designed to fit through drum openings, enabling safe and efficient transfer of liquids, chemicals, or viscous materials from industrial drums to tanks or process lines.

- Drum Heaters: Electric or steam heating bands used to maintain temperature-sensitive contents, prevent freezing, or aid in dispensing viscous materials.

- Spill Containment Pallets: Secondary containment systems that capture leaks or spills, ensuring compliance with environmental regulations.

- Drum Dollies and Lifters: Specialized handling equipment for safe, ergonomic transport of heavy drums around warehouses or job sites.

- Seals, Bungs, and Gaskets: Replacement parts to maintain drum integrity and prevent contamination or leaks.

Many suppliers offer industrial drum accessories tailored to your specific process or regulatory requirements.

Not sure which accessories you need? Consult our buyer’s guide or contact a drum specialist for expert recommendations.

Industry Standards and Compliance for 55-Gallon Drums

Ensuring compliance with industry standards is crucial for safety, legal, and operational reasons. The requirements for drums vary by application, industry, and regulatory environment:

- UN (United Nations) Standards: Drums used in international shipping must meet UN specifications for hazardous materials compatibility and performance testing.

- DOT (Department of Transportation): Any drum transported by road, rail, or air in the U.S. must comply with DOT requirements for packaging, labeling, and securement.

- FDA and USDA Regulations: For food, beverage, and pharmaceutical applications, drums must be manufactured from approved materials and meet strict hygiene and traceability guidelines.

- EPA and OSHA Standards: Drums used for hazardous waste or chemicals must adhere to EPA containment and OSHA workplace safety rules.

- Military, Healthcare, and Specialty Standards: Some sectors require additional certifications or performance testing for security, sterility, or environmental resistance.

If you’re uncertain about which standards apply to your project, consult with industry experts or regulatory authorities to ensure full compliance and risk mitigation.

How do I verify a drum meets required standards? Ask your supplier for certifications and compliance documentation before purchasing.

Buyer’s Guide: Sourcing and Selecting 55-Gallon Drums

Sourcing 55-gallon drums or other bulk storage solutions requires careful consideration of your application, regulatory needs, and long-term operational costs. Follow these steps for a successful procurement process:

- Define Your Application: Clearly identify whether you need drums for food, chemicals, water, waste, or another use. Consider factors such as chemical compatibility, required certifications, and intended storage conditions.

- Material Selection: Choose between steel, plastic, or fiber based on durability, cost, and regulatory requirements. For hazardous or reactive contents, consult a specialist to ensure safe material selection.

- Capacity and Size: While 55-gallon is standard, assess whether smaller (20, 30, 40-gallon) or larger custom sizes are more appropriate for your process or storage space.

- New vs. Reconditioned: Decide whether to purchase new drums or opt for reconditioned options to save costs and support sustainability. Ensure reconditioned drums are properly cleaned, tested, and certified for your application.

- Supplier Evaluation: Research potential vendors for track record, customer reviews, and product range. Request certifications, compliance documentation, and references if needed.

- Request Quotes and Compare: Narrow down your list to three or four suppliers that best meet your criteria. Request detailed quotes, including lead times, delivery options, and after-sales support.

- Consider Accessories and Customization: Factor in any required accessories (pumps, heaters, pallets) or custom modifications when evaluating total cost and supplier capabilities.

- Make an Informed Purchase: Compare offers, review documentation, and select the partner that provides the best value, reliability, and service.

Ready to get started? Browse our curated list of trusted 55-gallon drum manufacturers and suppliers.

Frequently Asked Questions About 55-Gallon Drums

- What are the most common uses for 55-gallon drums?

Drums are used for storing and transporting liquids, chemicals, food products, hazardous waste, and water. They are also repurposed for rainwater collection, composting, and creative DIY projects. - What is the difference between closed head and open head drums?

Closed head drums have a permanently sealed lid with a small opening for filling/dispensing, ideal for liquids. Open head drums have a removable cover for easy access to solids or viscous materials. - Are plastic drums safe for food and water storage?

Yes—if they are manufactured from FDA food-grade HDPE or other approved plastics and properly cleaned before use. - Can steel drums be used outdoors?

Steel drums can be used outdoors but may rust if not coated or made from stainless steel. Plastic drums are generally preferred for outdoor or wet environments. - How do I dispose of or recycle used drums?

Contact a licensed drum reconditioner or recycling facility. Many drums can be cleaned, reconditioned, and reused, while others are accepted at metal or plastic recycling centers depending on material and contamination. - How much does a 55-gallon drum weigh?

Empty steel drums weigh approximately 40-50 lbs; plastic drums typically weigh 20-25 lbs. Weights vary by manufacturer and design.

Have a specific question about 55-gallon drums? Contact a supplier or browse our knowledge base for expert answers.

Explore More Bulk Storage Solutions

In addition to 55-gallon drums, businesses often need related products for their logistics and material handling operations. Plastic pallets are a popular choice for safe, hygienic, and cost-effective bulk transportation.

Check out our Plastic Pallets website for more information on industry-leading pallet manufacturers, types, and buying tips.

Still searching for the perfect bulk container or accessory? Browse our comprehensive directory of 55-gallon drum suppliers, or use our site search for other storage solutions.

55 Gallon Drums

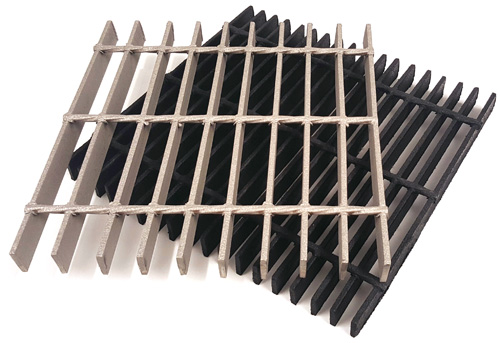

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services