These barrel manufactures are skilled and experienced in working with a wide range of materials, from metals to plastics in order to achieve the right style and properties that their clients require based on their application specifications and needs. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

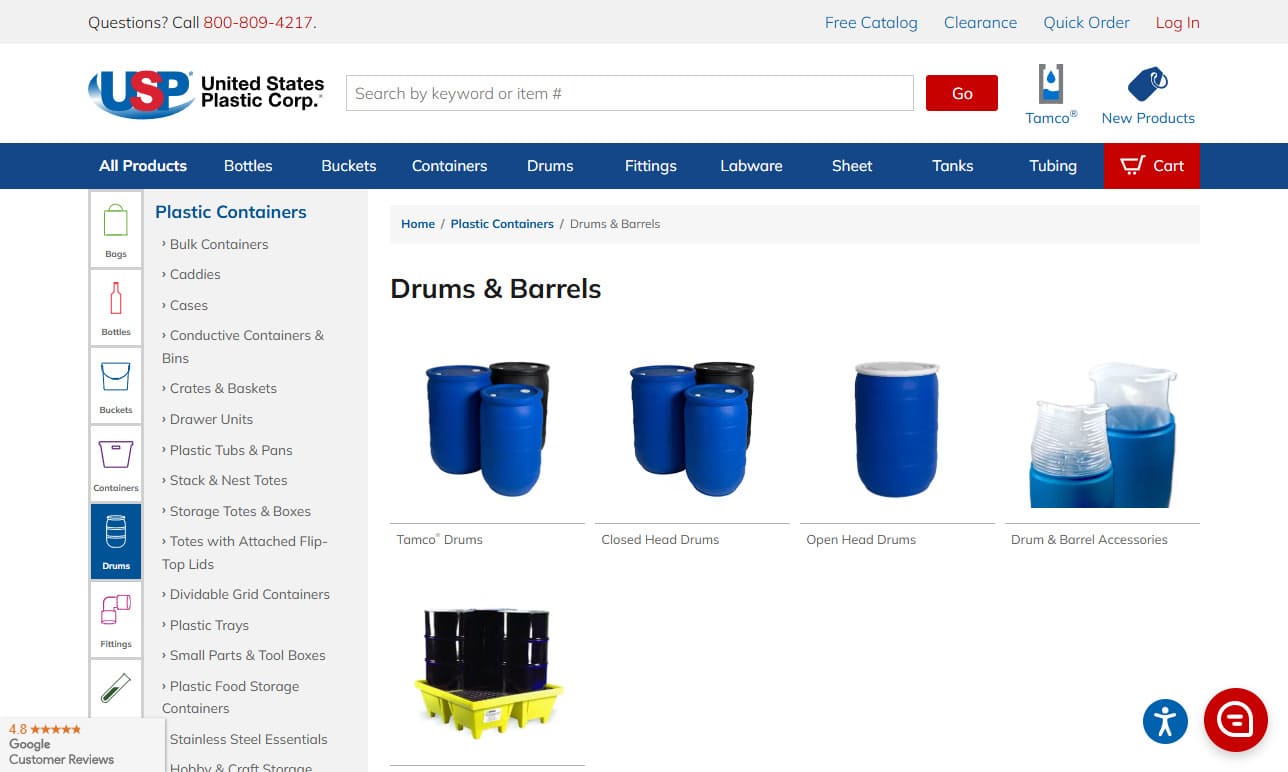

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More Barrel Manufacturers

Choosing the Right Shipping Barrel or Drum: A Comprehensive Guide

Are you searching for the best shipping containers, industrial barrels, or storage drums for your business or personal needs? Understanding the different types of barrels and drums available, their key features, and how to select a trusted, experienced barrel manufacturer can make all the difference in ensuring your goods are stored and transported safely, efficiently, and in compliance with industry regulations.

When evaluating options for shipping containers, cylindrical barrels are among the most versatile choices. Whether you require solutions for liquid transport, hazardous materials, food-grade storage, or industrial bulk packaging, working with a knowledgeable barrel manufacturer who tailors products to your specific application is crucial. Explore the full landscape of barrel and drum solutions to maximize safety, regulatory compliance, and cost-effectiveness in your operations.

Why Barrel Selection Matters in Shipping and Storage

The decision to purchase a barrel or drum is more than a simple matter of size or shape. The right container must meet stringent shipping standards, industry regulations, and application-specific requirements. For businesses handling chemicals, pharmaceuticals, food products, oils, hazardous waste, or sensitive goods, the proper barrel design ensures:

- Compliance with DOT, UN, and international shipping regulations

- Leak-proof containment and protection against contamination

- Safe handling and ease of transport

- Compatibility with automation or material handling systems

- Cost efficiency and product longevity

For example, failing to use a drum certified for hazardous materials can result in fines, environmental risks, and compromised safety. That's why it's essential to partner with a barrel supplier who understands regulatory frameworks and can recommend the appropriate materials and features for your industry.

Types of Barrels and Drums: Finding the Best Fit

Barrels and drums come in a wide array of types, sizes, and materials. The most common drum types include:

1. Open Top Drums

Open top drums, also known as removable head drums, feature a detachable lid secured by a locking ring. This design is ideal for applications where:

- Frequent access to contents is required

- Products need to be loaded or unloaded in bulk

- Storage of solid materials, powders, or granules is needed

- Cleaning and reusing containers is a priority

Open head drums are popular for temporary storage, waste collection, recycling, and industries like food processing, agriculture, and manufacturing. They are available in various materials, including steel open head barrels, plastic open head drums, and fiber drums.

2. Welded Top Drums (Tight Head Drums)

Welded top drums, also referred to as tight head barrels, have a sealed, non-removable lid with bung openings. These are the preferred choice for liquid shipping and long-term storage where maximum leak resistance is essential. Common use cases include:

- Transporting oils, chemicals, and hazardous liquids

- Industrial bulk packaging for solvents or fuels

- Shipping food-grade products and beverages

- Long-distance export or import operations

Tight head drums are engineered for durability and compliance with international transport regulations. Material options include carbon steel drums, stainless steel drums, and high-density polyethylene (HDPE) tight head drums.

Materials: Steel, Plastic, and Fiber Barrels

Choosing the right material for your barrel or drum impacts performance, durability, and regulatory compliance. Consider the following options:

Steel Barrels

- Best for: Flammable liquids, hazardous chemicals, and high-value commodities

- Benefits: Robust structure, excellent chemical resistance, long lifespan, suitable for UN/DOT certification

- Applications: Oil & gas, pharmaceuticals, paint & coatings, industrial waste

Plastic Drums

- Best for: Non-corrosive liquids, food products, pharmaceuticals, and water storage

- Benefits: Lighter weight, rustproof, cost-effective, available in FDA-approved food-grade versions

- Applications: Agriculture, beverage production, food service, sanitation

Fiber Drums

- Best for: Dry solids, pharmaceuticals, powders, and light bulk materials

- Benefits: Lightweight, recyclable, customizable sizes, ideal for dry packaging

- Applications: Chemical processing, food ingredients, powder coating, waste collection

Still unsure which material is right for your use case? Contact a drum expert or explore our Barrel & Drum FAQ for detailed guidance.

Industry-Specific Applications and Use Cases

Barrels and drums are indispensable in a variety of industries, each with unique requirements:

- Food & Beverage: Secure storage and transport of edible oils, flavorings, syrups, and beverages using food-grade barrels.

- Chemical Manufacturing: Compliance with hazardous material shipping regulations, spill containment, and chemical compatibility.

- Agriculture: Bulk storage and shipment of grains, fertilizers, pesticides, and animal feed.

- Pharmaceutical: Clean, contaminant-free barrels for active ingredients and finished medications.

- Waste Management: Collection and disposal of hazardous waste, recycling, and regulated materials in DOT/UN-approved drums.

- Oil & Gas: Transport and storage of lubricants, crude oil, and industrial fluids in heavy-duty steel barrels.

- Construction: Storage of adhesives, paints, coatings, and bulk building materials.

Are you seeking a custom solution for a unique application? Request a custom barrel quote to discuss your project's needs with an industry expert.

Critical Factors in Choosing a Barrel Manufacturer

With so many options on the market, how do you select the best barrel manufacturer or drum supplier? Consider the following decision factors to ensure you receive a product that meets your requirements and exceeds expectations:

- Industry Experience: Choose manufacturers with a proven track record in your sector (e.g., chemical, food, pharmaceutical, industrial packaging).

- Customization Capabilities: Look for suppliers who offer custom sizing, fittings, coatings, color options, and branding.

- Regulatory Compliance: Ensure the manufacturer provides certification for DOT, UN, or FDA standards as required by your application.

- Quality Assurance: Ask about in-house testing, traceability, and quality control processes.

- Technical Support: Work with partners who offer design assistance, regulatory guidance, and responsive customer service.

- Delivery & Logistics: Consider lead times, shipping costs, and the ability to deliver in your region or internationally.

- Reputation & Reviews: Check references, case studies, and client testimonials to verify vendor reliability.

Ready to compare barrel manufacturers? Browse our list of top-rated drum suppliers or request a quote for your next project.

Frequently Asked Questions: How to Buy Barrels and Drums

- What is the difference between an open head and a tight head drum?

Open head drums have a removable lid for easy access, ideal for solids and powders, while tight head drums have a sealed top with small openings for liquids and hazardous materials. - Which barrel material should I choose?

Select steel for chemical and hazardous goods, plastic for food or water, and fiber for dry bulk materials. Need more help? Ask our experts. - Are there regulations for shipping hazardous materials?

Yes, use DOT/UN-certified drums to comply with US and international shipping laws. Always verify requirements before purchase. - Can I get custom barrels or drums?

Many manufacturers offer custom sizes, fittings, and coatings. Get a custom quote today. - What are common barrel sizes and capacities?

Standard sizes include 55-gallon (208L), 30-gallon (114L), and 15-gallon (57L) drums, but custom sizes are available for specialty uses.

Best Practices for Barrel and Drum Procurement

To ensure a successful purchase and seamless integration into your logistics or storage operations, follow these best practices:

- Define your application and necessary certifications (e.g., UN, FDA, DOT).

- Specify material compatibility based on contents (chemical, food, waste, etc.).

- Consult with multiple drum manufacturers to compare capabilities and pricing.

- Request samples or product specifications before bulk ordering.

- Plan for delivery, storage, and handling at your facility.

- Establish a relationship with a supplier for ongoing support and reorders.

Looking for tips on how to optimize your packaging process? Read our guide on efficient drum handling and logistics.

Benefits of Working with a Trusted Barrel Manufacturer

Partnering with a reputable barrel manufacturer or industrial drum supplier offers several compelling benefits:

- Expert guidance: Access technical know-how for complex regulatory and material decisions.

- Product reliability: Receive barrels and drums engineered for your specific needs and certified for safety and compliance.

- Custom solutions: Tailor drums to your dimensions, branding, and special requirements.

- Long-term value: Build an ongoing partnership for consistent quality and supply chain efficiency.

- Resource optimization: Reduce waste, minimize compliance risks, and improve overall operational effectiveness.

Not sure where to start? Schedule a free consultation with our team to discuss your storage and shipping needs.

How to Get Started: Requesting a Quote or Consultation

Ready to take the next step in sourcing high-quality barrels or drums for shipping, storage, or industrial use? Here’s how you can begin:

- Assess Your Needs: Define the contents, volume, and required certifications for your application.

- Research Suppliers: Use our supplier directory or request recommendations from industry peers.

- Request Quotes: Contact multiple barrel manufacturers for pricing, lead times, and customization options.

- Evaluate Offers: Compare quality assurances, references, and after-sales support.

- Place Your Order: Confirm specifications and delivery details to ensure a smooth procurement process.

For immediate assistance or to discuss your unique requirements, contact us now.

Explore Further: Related Resources and Buyer Guides

- Guide to Barrel and Drum Types: Steel, Plastic, Fiber

- Understanding Shipping Regulations for Industrial Drums

- Industry Applications for Barrels and Drums

- How to Clean and Maintain Storage Drums

- Sustainable Reuse and Recycling of Industrial Barrels

Let us help you find the perfect drum or barrel for your next project. Whether you’re shipping chemicals, storing food products, or managing industrial waste, we have the expertise and product range to meet your needs. Reach out today to get started.

55 Gallon Drums

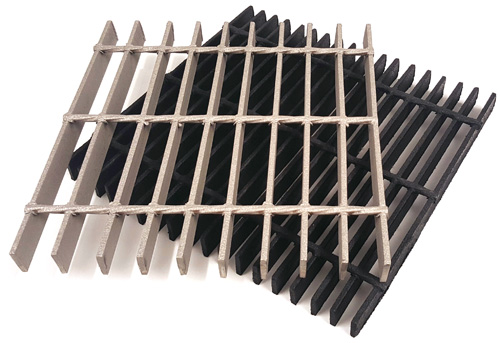

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services