Steel offers its customer a wide range of applications, including in the oil, lubricant, fertilizer and paint industries, as well as in the edible products market. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

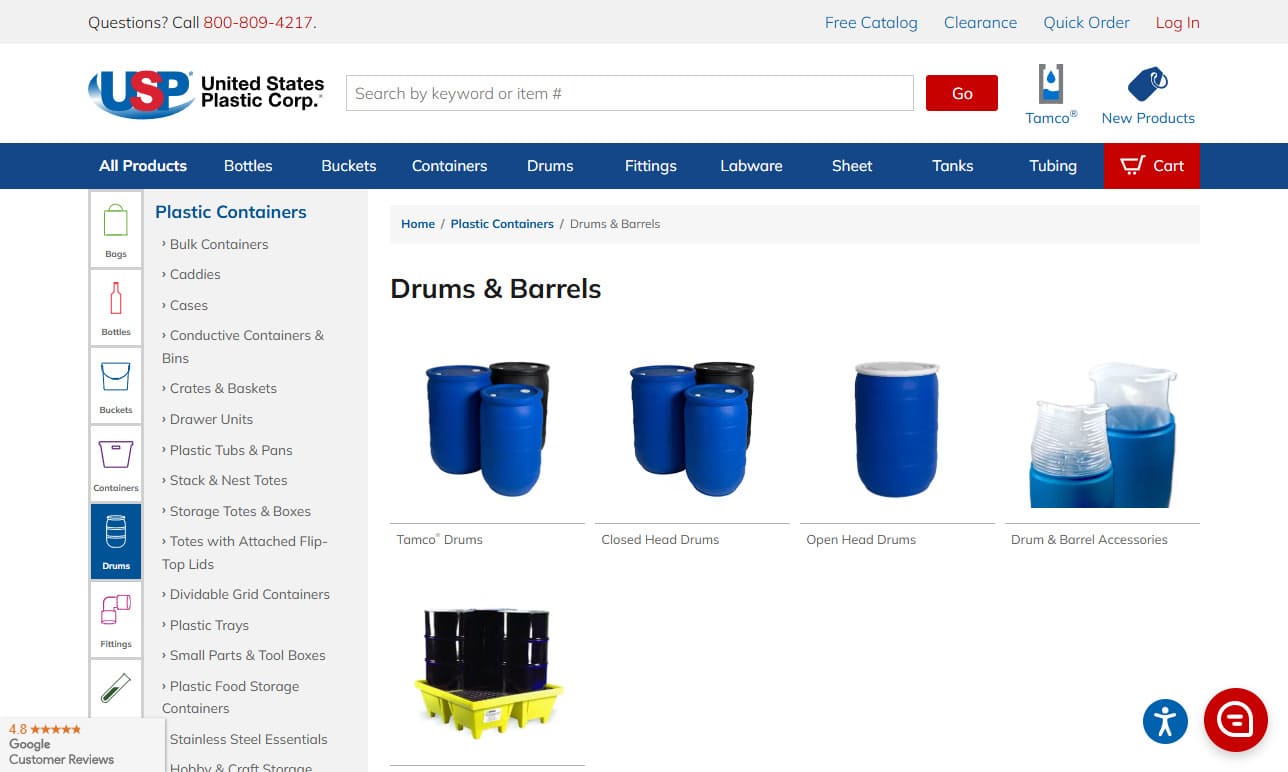

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More 30 Gallon Steel Drum Manufacturers

Comprehensive Guide to 30 Gallon Steel Drums: Customization, Linings, and Industrial Applications

30 gallon steel drums are a highly versatile and durable packaging solution widely used across numerous industries for the storage, transport, and handling of liquids, powders, chemicals, hazardous materials, and food-grade products. Their popularity stems from their robust construction, customizable features, and ability to meet stringent safety and regulatory standards for industrial packaging. Whether you are evaluating drum types for hazardous waste disposal, food processing, or chemical storage, understanding the options and benefits of 30 gallon steel drums can help you make an informed purchasing decision.

Customization Options for 30 Gallon Steel Drums

Thirty gallon steel drums can be customized in a number of ways to fit specific storage and handling requirements. Customization is a crucial consideration for buyers who need to ensure compatibility with their product type, regulatory compliance, and operational workflows. Common customization features include:

- Interior Linings: Steel drums may be fitted with a variety of interior linings. For instance, an unlined interior can be plain carbon steel or steel sprayed with a rust inhibitor for general-purpose use. Internal linings are available in a wide range of materials and formulations, including phenolic coatings, epoxy-phenolic coatings, and other specialty coatings designed to protect the steel from reactive or corrosive contents. These linings help prevent contamination, preserve product integrity, and extend drum lifespan.

- Liner Accessories: In addition to permanent drum linings, 30 gallon steel drums can be equipped with disposable or reusable liners. Not to be confused with linings, liners are removable inserts that provide an extra layer of containment and can simplify drum cleaning and maintenance. Liners are available as optional accessories and can be tailored to specific applications.

- Closure Types: Buyers can select between open-head (removable top) and tight-head (sealed top with bung openings) designs based on intended use. Open-top steel drums allow for easy filling and dispensing of bulk solids or viscous materials, while tight-head drums are ideal for secure storage and transportation of liquids and hazardous substances.

- Exterior Coatings: Additional customization includes exterior coatings such as epoxy paint, powder coating, or specialty finishes to improve corrosion resistance, enhance drum identification, and meet corporate branding requirements.

Types of Liners and Their Applications

Choosing the right liner is essential for maximizing the performance and hygiene of 30 gallon steel drums, especially in industries with strict sanitation or contamination control standards. Liners act as a protective barrier between the drum’s interior and its contents, making them indispensable in food, pharmaceutical, and chemical processing environments.

- Round Bottom Liners: Round bottom or molded liners are recommended for open-top steel drums. These liners are typically made from clear, low-density polyethylene (LDPE) plastic and are designed to conform to the drum’s interior, creating an effective seal without bunching or gathering in the creases. Round bottom liners are particularly well suited for bulk processing and packaging of food, pharmaceuticals, chemicals, adhesives, sealants, coatings, inks, dyes, paints, varnishes, colorants, dairy products, concrete, and both liquid and powdered substances.

- Molded Liners: Molded liners, also made from LDPE, are available in smooth or accordion (pleated) styles. Smooth liners enable complete product recovery, minimizing waste and facilitating efficient cleaning. Accordion liners are adjustable to various heights, making them ideal for applications where drum fill level can vary. Molded liners feature a lip that secures them in place, ensuring they remain properly positioned during use. These liners are recommended for drums subjected to high-stress processes such as high-speed mixing, pumping, or agitation of viscous and abrasive materials, as they resist bending and cracking.

- Drum Liner Selection Tips: When choosing between round bottom, molded, or accordion liners, consider the viscosity of your product, temperature requirements, chemical compatibility, and the need for full product recovery. Selecting the right liner can help you optimize production efficiency and reduce costs related to cleaning and contamination.

Did you know? Liners not only extend the life of your steel drums but also help maintain product purity, prevent cross-contamination, and speed up changeovers between different products. Looking for guidance on drum liner compatibility? Ask us about liner materials for specific chemicals, food products, or industrial applications.

Key Benefits and Advantages of 30 Gallon Steel Drums

Steel drums are an advantageous choice for a number of reasons, making them a staple in industrial packaging, bulk material handling, and hazardous waste management. Here are some of the top benefits:

- Exceptional Durability: Constructed of high-quality cold-rolled or hot-rolled steel, 30 gallon drums are engineered to withstand rough handling, stacking, and transportation stresses. They are less prone to punctures, dents, or leaks compared to plastic or fiber drums.

- Thermal Resistance: Steel drums can withstand extreme temperatures, ranging from -30°F to 250°F (-34°C to 121°C). This makes them ideal for applications involving hot-fill processes, autoclaving, or outdoor storage in varying climates.

- Chemical and Corrosion Resistance: With appropriate linings or coatings, steel drums offer excellent resistance to a wide range of chemicals, solvents, oils, and corrosive materials. This is essential for safely storing and transporting hazardous waste, industrial chemicals, and sensitive food or pharmaceutical products.

- Regulatory Compliance: Most 30 gallon steel drums are manufactured to meet or exceed UN/DOT regulations for the transport of hazardous substances. They are also compliant with FDA, USDA, and other industry standards for food and pharmaceutical packaging when equipped with suitable linings or liners.

- Reusable and Recyclable: Steel drums are designed for multiple reuse cycles, offering a more sustainable and cost-effective packaging solution. At the end of their service life, they are 100% recyclable, supporting circular economy initiatives.

- Versatile Applications: Suitable for storing and shipping chemicals, food ingredients, flavorings, adhesives, lubricants, coatings, paints, resins, oils, hazardous waste, and a wide range of industrial or agricultural materials.

Still wondering, “Are steel drums the best choice for my material or process?” Contact our experts for recommendations tailored to your specific use case, compliance requirements, and budget.

Common Use Cases and Industry Applications

30 gallon steel drums are employed in a diverse array of industries. Their robust construction, compatibility with various liners and coatings, and compliance with strict regulations make them the packaging of choice for many demanding applications, including:

- Chemical Manufacturing and Distribution: For the safe storage and transport of acids, solvents, resins, lubricants, and industrial chemicals requiring superior containment and leak prevention.

- Pharmaceutical and Food Processing: Used for hygienic storage, batching, and blending of bulk powders, food ingredients, flavorings, dairy products, and pharmaceutical intermediates. When fitted with FDA-approved linings and liners, steel drums meet stringent sanitary standards.

- Paints, Coatings, and Adhesives: Ideal for high-viscosity liquids and products sensitive to contamination or moisture ingress. Specialized linings help preserve product quality and shelf life.

- Hazardous Waste Management: Commonly used for the collection, temporary storage, and transport of hazardous waste, including regulated chemicals, contaminated soil, or cleanup debris. Drums are UN/DOT certified for hazardous materials.

- Construction and Concrete Additives: Used for packaging, transporting, and dispensing admixtures, colorants, and concrete curing compounds safely and efficiently on job sites.

- Inks, Dyes, and Colorants: Steel drums with appropriate coatings provide a contamination-free environment for high-purity colorants, inks, and dyes used in printing and manufacturing.

- Other Industrial and Agricultural Applications: From lubricants and greases to water treatment chemicals and agricultural inputs, steel drums offer secure, long-lasting storage solutions.

Curious about how 30 gallon steel drums can fit into your workflow? Explore:

- How to select the right drum liner for your materials and processes?

- What regulatory standards apply to your industry?

- Sustainability and reconditioning options for steel drums.

How to Select the Right Steel Drum Liner

Choosing the ideal drum liner involves balancing product compatibility, regulatory requirements, and operational needs. Here’s a step-by-step guide to help you evaluate your options:

- Identify Product Characteristics: Consider whether your product is a liquid, powder, or viscous material, and note any special requirements for temperature, chemical resistance, or cleanliness.

- Review Regulatory Standards: Determine if your application requires FDA, USDA, or UN/DOT compliant liners. This is critical for food, pharmaceutical, and hazardous material uses.

- Assess Liner Material: Common choices include low-density polyethylene (for general chemical and food use), high-density polyethylene (for more aggressive chemicals), and specialty barrier films for solvent-sensitive applications.

- Choose Liner Design: Decide between round bottom, molded, accordion, or flat bottom liners based on how you fill, empty, or clean your drums.

- Consider Ease of Use and Product Recovery: Accordion liners allow for height adjustment, while smooth liners maximize complete product recovery, reducing waste and cleaning time.

Need help choosing? Request a liner compatibility chart or expert consultation based on your specific product and industry.

Regulatory Standards: What to Know Before You Buy

Compliance is a top priority when sourcing 30 gallon steel drums for regulated industries. Here are the key standards and certifications to look for:

- UN/DOT Certification: Required for the transport of hazardous materials, ensuring drums have passed rigorous leak, drop, and pressure testing.

- FDA and USDA Approvals: For food and pharmaceutical applications, look for drums and liners that are certified food-safe and free of harmful contaminants.

- ISO Standards: International standards such as ISO 15750 and ISO 20848 specify requirements for steel drum design and performance.

- Customer-Specific Standards: Some industries or companies may require proprietary coatings, color coding, or labeling to meet internal quality control or traceability requirements.

Ask yourself: Are you confident your packaging partner can provide documentation and support for regulatory compliance? If not, speak with a compliance specialist for guidance on documentation, labeling, and certification.

Sustainability, Reconditioning, and Cost-Saving Strategies

Steel drums are a leading choice for companies seeking sustainable and cost-effective industrial packaging solutions. Here’s why:

- Reusability: High-quality 30 gallon steel drums are designed for repeated use, with many drums capable of lasting years with proper care and maintenance. This reduces the need for frequent drum replacement and cuts down on packaging waste.

- Reconditioning Services: Many suppliers offer drum reconditioning, cleaning, and re-certification services. Reusing drums not only saves on procurement costs but also supports waste reduction and resource conservation.

- 100% Recyclable: At the end of their usable life, steel drums are fully recyclable. Scrap steel can be melted down and repurposed into new steel products, supporting closed-loop recycling.

- Lower Total Cost of Ownership: While steel drums may have a higher upfront cost than plastic or fiber alternatives, their long lifespan, reusability, and recyclability contribute to lower total packaging costs over time.

Looking for ways to enhance your operation’s sustainability profile? Ask about reconditioned steel drum availability, recycling programs, and environmental certifications.

Decision Factors: How to Choose the Best 30 Gallon Steel Drum Supplier

Selecting the right supplier is critical to ensuring consistent product quality, regulatory compliance, and reliable service. Here’s what to evaluate when comparing 30 gallon steel drum vendors:

- Product Range and Customization: Does the supplier offer a broad selection of drum types, linings, liners, and closure options to meet your specific requirements?

- Certifications and Compliance: Can the supplier provide documentation for UN/DOT, FDA, USDA, or ISO compliance as needed?

- Lead Times and Delivery: Are inventory levels and shipping logistics aligned with your production schedule?

- Technical Support: Does the supplier offer expert guidance on liner selection, chemical compatibility, safety, and regulatory issues?

- Reconditioning and Recycling: Are take-back, cleaning, or recycling services available to support your sustainability initiatives?

- Reputation and Reviews: What do other customers say about the supplier’s product quality, customer service, and responsiveness?

Ready to request a quote or compare options? Get in touch with a steel drum specialist for personalized recommendations and bulk pricing.

Frequently Asked Questions About 30 Gallon Steel Drums

- What are the main differences between steel, plastic, and fiber drums? Steel drums offer superior strength, temperature resistance, and chemical compatibility, making them ideal for hazardous or heavy-duty applications. Plastic drums are lighter and corrosion-resistant, suitable for non-hazardous liquids. Fiber drums are best for dry goods and light-duty use.

- Can 30 gallon steel drums be used for food-grade applications? Yes, when equipped with FDA-approved liners and coatings, steel drums are safe for storing and transporting food, flavorings, and ingredients.

- Are reconditioned steel drums as reliable as new drums? When properly cleaned, tested, and recertified, reconditioned drums meet the same safety and regulatory standards as new drums, offering a cost-effective and sustainable alternative.

- How do I order drums with custom linings or liners? Work with a supplier who offers customization. Specify your requirements for lining type, liner style, closure configuration, and certifications.

- What is the typical lead time for bulk steel drum orders? Lead times vary by supplier and order size but typically range from 2-6 weeks for standard and custom drum configurations.

Have more questions or need expert advice? Contact our team for detailed product specifications, regulatory support, and a free consultation.

Summary: Why Choose 30 Gallon Steel Drums for Your Industrial Packaging Needs?

30 gallon steel drums offer unmatched durability, safety, and versatility for industrial packaging and material handling. With a wide array of customization options—including linings, liners, closure types, and coatings—these drums can be tailored to virtually any application, from hazardous waste disposal and chemical manufacturing to food processing and pharmaceuticals. Their compliance with global regulations, reusability, and recyclability make them an environmentally responsible and cost-effective choice for businesses seeking secure, long-term bulk packaging solutions.

To learn more, request a quote or speak with a steel drum expert today. Discover how the right 30 gallon steel drum can enhance your operational efficiency, protect your products, and support your sustainability goals.

55 Gallon Drums

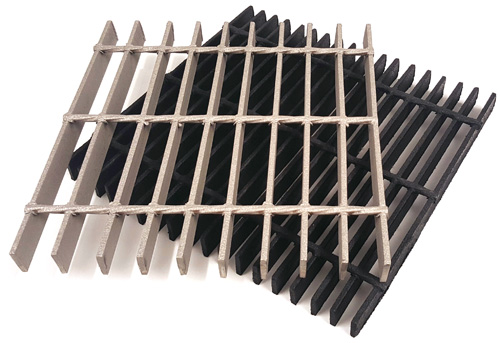

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services