The word “barrel” is often used interchangeable with “drum,” and the two are almost identical. Thirty gallon barrels are barrels of medium size, and they have use in many industries, depending on their composition. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

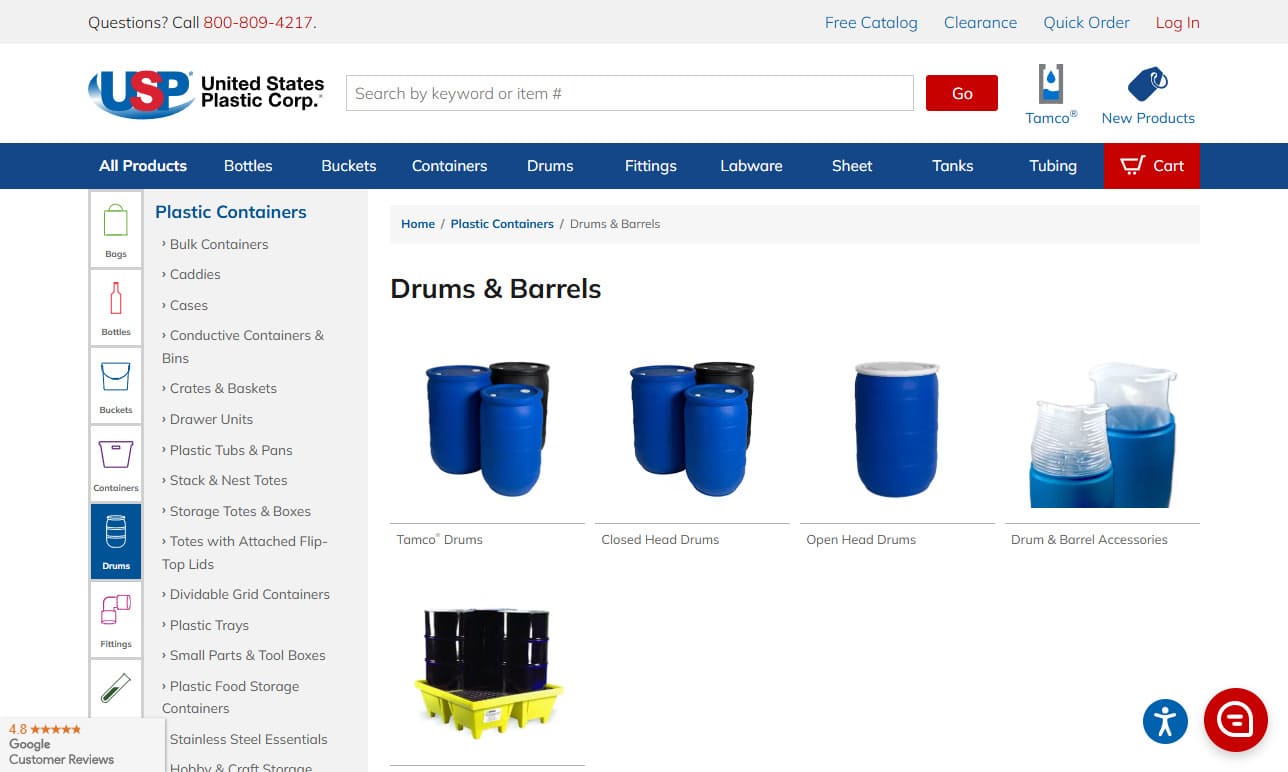

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At Best Containers, we have built our reputation around providing dependable storage and transport solutions, with our 55 gallon drums standing as one of the most trusted products we distribute. We recognize that businesses across a wide range of industries—from chemical and pharmaceutical to food processing and industrial manufacturing—rely on strong, secure, and compliant containers, and we ...

At BayTec Service, we specialize in providing a wide range of industrial container solutions, with a strong focus on 55-gallon drums that serve customers across countless sectors. We take pride in being a reliable source for steel, plastic, and fiber drums, all crafted to meet rigorous standards for quality, safety, and durability.

More 30 Gallon Barrel Manufacturers

30 Gallon Barrels: Comprehensive Guide to Plastic, Metal, and Stainless Steel Options

For centuries, barrels have played a pivotal role in the safe storage and transport of liquids and dry goods. While wooden barrels continue to evoke tradition, modern industries are increasingly turning to 30 gallon barrels made from plastic, steel, and stainless steel for their superior performance, versatility, and regulatory compliance. This guide explores the different types of 30 gallon barrels, their industrial uses, key benefits, and the main factors to consider when selecting the ideal container for your application.

What Are 30 Gallon Barrels Used For?

30 gallon barrels serve as an essential solution across a wide range of industries for both liquid and solid containment. Their manageable size and durable construction make them ideal for:

- Storing and aging wine, beer, and spirits in the beverage and distilling industries

- Transporting chemicals, solvents, and hazardous materials in manufacturing and laboratory environments

- Collecting rainwater, composting, and storing animal feed in agricultural and gardening settings

- Distributing food ingredients, syrups, and edible oils in food processing and distribution

- Safeguarding aviation fuel and sensitive liquids in the aviation and defense sectors

- Supporting emergency preparedness, spill response kits, and disaster relief logistics

Are you wondering whether a 30 gallon barrel is right for your specific needs? Contact us for tailored recommendations or read on to explore the unique features of each barrel type.

Types of 30 Gallon Barrels: Material Comparison

1. Stainless Steel 30 Gallon Barrels

Stainless steel barrels have surged in popularity, especially in wine-making and food-grade storage, due to their combination of durability, hygiene, and chemical resistance. Unlike traditional wooden barrels, modern stainless steel 30 gallon barrels offer:

- Non-porous surfaces that prevent flavor contamination, ensuring product purity

- Superior corrosion resistance and ability to withstand extreme temperatures

- Ease of cleaning and sanitization, making them ideal for repeated use and compliance with food safety standards

- Reduced maintenance costs and a longer service life compared to wood or less robust metals

- Recyclability, supporting sustainable operations and environmental stewardship

Common stainless steel barrel applications include:

- Fermentation and aging of wine, beer, and spirits

- Storage of pharmaceutical and laboratory chemicals

- Containment of high-value or sensitive liquids requiring strict hygiene

- Transporting bulk food ingredients, flavorings, and essential oils

Why Choose Stainless Steel Barrels?

Wondering if stainless steel is the best choice for your operation? Stainless steel 30 gallon barrels are renowned for their ability to prevent leaching of flavors or chemicals, making them a preferred option in sectors where product integrity is non-negotiable. Their robust build also allows for high-pressure applications and repeated sanitation cycles, reducing lifecycle costs. If your workflow demands top-tier hygiene, corrosion resistance, or compliance with FDA or NSF regulations, stainless steel is often the optimal solution.

2. Plastic 30 Gallon Barrels

Plastic barrels—primarily manufactured from high-density polyethylene (HDPE)—are prized for their lightweight design, chemical resistance, and cost-effectiveness. They are a mainstay in industries seeking versatile, weather-resistant, and easily transportable containers.

- Outstanding resistance to corrosive chemicals, acids, bases, and solvents

- Weatherproof and UV-resistant coatings for outdoor storage and long-term use

- Available in multiple colors for easy content identification and regulatory compliance

- Suitable for both indoor and outdoor applications, including rainwater harvesting, irrigation, and composting

- Often equipped with UN/DOT certification for transport of hazardous materials

Key use cases for plastic 30 gallon barrels include:

- Rainwater collection systems and sustainable irrigation

- Spill containment, emergency kits, and hazardous waste management

- Bulk food ingredient storage and food-grade applications

- Supporting industrial recycling and waste collection programs

- Packaging and shipping in pharmaceutical, cosmetic, and agricultural sectors

Curious about the right color or configuration for your application? Explore plastic barrel options or request a quote for custom features like wheels, spigots, or secure lids.

Advantages of HDPE Plastic Barrels

HDPE plastic offers a remarkable combination of strength, impact resistance, and chemical inertness, making it the go-to material for reliable liquid and dry goods storage. With options for closed-head (tight head) and open-head (removable lid) designs, users can select the ideal configuration for their filling, dispensing, or cleaning requirements. Plastic drums are also widely used as rain barrels, compost bins, and even DIY projects due to their flexibility, safety, and affordability.

3. Steel 30 Gallon Barrels

Steel barrels, often constructed from carbon steel or galvanized steel, offer unmatched strength and fire resistance. These containers are essential in industries where the storage or transport of flammable, volatile, or high-value substances is routine.

- High strength and puncture resistance for maximum safety

- Suitable for storing fuels, oils, lubricants, and chemicals

- Can withstand extreme temperatures, making them ideal for industrial and laboratory use

- Compatible with a wide range of closure systems and safety accessories

- Reusable, recyclable, and compliant with UN/DOT regulations for hazardous materials

Typical applications for steel 30 gallon barrels:

- Transport and storage of aviation fuel and other combustibles

- Containment of industrial solvents, lubricants, and coolants

- Safe handling and storage of laboratory chemicals and hazardous waste

- Support for disaster preparedness and emergency response operations

Steel vs. Stainless Steel: Which Is Best?

Choosing between steel and stainless steel barrels depends on your priorities. For maximum corrosion resistance, especially in food or pharmaceutical applications, stainless steel is preferable. For heavy-duty, cost-sensitive, or high-temperature environments, carbon steel barrels provide superior strength and economy. Both types are available with a variety of accessories and closure systems to ensure safe handling and compliance with relevant safety standards.

Key Features and Customization Options

30 gallon barrels are highly customizable to meet the requirements of diverse applications. When considering which barrel to purchase, evaluate these common features and add-ons:

- Open-head vs. closed-head: Open-head barrels (removable lid) allow for easy filling and cleaning, while closed-head (tight head) barrels offer leak-proof security for liquids.

- Color coding: Plastic barrels can be manufactured in various colors to distinguish contents, prevent cross-contamination, or comply with regulatory requirements.

- Accessories: Enhance safety and convenience with drum bung spanners, tab seal removers, drum trolleys, tilting levers, safety funnels, inspection lights, heaters, and more.

- Mobility solutions: Add wheels or dollies for easy transport in warehouses, factories, or field environments.

- Recycling and environmental options: Select barrels made from recycled materials or designed for easy end-of-life recycling.

- UN/DOT Certification: Ensure your barrel meets national and international standards for the safe transport of hazardous or regulated materials.

Looking for a specific configuration or accessory? Request a custom quote or browse our full catalog to compare options side-by-side.

Industry Applications: Where Are 30 Gallon Barrels Essential?

The flexibility and reliability of 30 gallon barrels have made them indispensable in:

- Food and Beverage: Storage, fermentation, and shipping of wine, beer, spirits, juices, oils, and syrups. Compliance with FDA food-grade standards is crucial for these applications.

- Chemical Processing: Handling and transport of acids, solvents, detergents, and laboratory reagents, where chemical compatibility and leak-proof construction are essential.

- Agriculture and Horticulture: Rainwater harvesting, irrigation, composting, fertilizer storage, and animal feed containment, with an emphasis on weather resistance and safe handling.

- Waste Management and Recycling: Collection and transport of recyclables, hazardous waste, and industrial byproducts, utilizing color-coded and labeled barrels for compliance and safety.

- Emergency Planning: Spill response kits, disaster relief logistics, and emergency water or fuel storage, where portability and rapid deployment are mission-critical.

- Defense and Aviation: Secure storage and transport of fuels, chemicals, and sensitive materials, often requiring UN/DOT-certified steel or stainless steel barrels.

- Laboratory Research: Containment of reagents, solvents, and hazardous samples, necessitating sterile, chemically-resistant containers.

Frequently Asked Questions: Choosing the Right 30 Gallon Barrel

- What is the difference between open-head and closed-head barrels?

Open-head barrels have a removable lid for easy filling, cleaning, and dispensing of solids or viscous materials. Closed-head (tight head) barrels have a sealed top with bung openings, providing superior leak resistance for liquids and hazardous materials. - Are 30 gallon barrels food-safe?

Yes, both plastic and stainless steel barrels can be manufactured to food-grade standards, ensuring compliance with FDA and other relevant regulations. - How do I safely handle and transport barrels?

Use approved drum handling equipment such as drum trolleys, tilting levers, and appropriate personal protective equipment (PPE). For hazardous or heavy contents, always follow OSHA guidelines and relevant local regulations. - Can I recycle used 30 gallon barrels?

Most plastic and steel barrels are fully recyclable. Check with your local recycling provider or contact us for information on reconditioning and recycling programs. - Which barrel material is best for storing chemicals?

For most chemicals, HDPE plastic offers excellent resistance. For particularly volatile or corrosive substances, stainless steel or lined steel barrels may be required. Always verify chemical compatibility before use. - How long do 30 gallon barrels last?

With proper care, plastic barrels can last 10+ years, while stainless steel barrels may last decades. Lifespan depends on usage, storage conditions, and exposure to chemicals or sunlight.

How to Select the Right 30 Gallon Barrel for Your Business

When evaluating 30 gallon barrel suppliers and products, consider the following criteria:

- Material compatibility: Match the barrel material to your contents (chemicals, food, fuel, etc.) and required regulatory standards.

- Certification and compliance: Ensure barrels are certified for hazardous materials if needed (UN/DOT, FDA, NSF, etc.).

- Intended use: Consider whether you need open-head or closed-head barrels, color coding, or specific accessories.

- Durability and weather resistance: For outdoor or harsh environments, prioritize UV-resistant plastics or corrosion-resistant metals.

- Cost and sustainability: Factor in initial investment, expected lifespan, and recyclability for long-term value.

- Supplier reputation: Work with reputable distributors who offer technical support, documentation, and responsive customer service.

Ready to find the perfect 30 gallon barrel for your operation? Contact our experts for personalized guidance, or browse our in-depth plastic barrel selection for more details on available models and specifications.

Benefits of Using 30 Gallon Barrels

Adopting 30 gallon barrels in your workflow delivers measurable advantages:

- Optimal Size: Large enough for bulk storage, yet compact for easy handling and transport

- Cost-Effective: Lower shipping and handling costs compared to larger drums; less waste if smaller quantities are needed

- Regulatory Compliance: Available with certifications for food-grade, hazardous, or pharmaceutical use

- Versatility: Suitable for liquids, solids, hazardous materials, and food products

- Environmental Responsibility: Many options for recycled materials or end-of-life recycling programs

- Customization: Wide range of accessories and configurations for specialized needs

Looking to maximize efficiency and safety in your storage or transport operations? Explore our 30 gallon barrel solutions for every industry and application.

Explore Related Resources

- Plastic Barrel Types and Applications

- Steel Drum Selection Guide

- Fiber Drum Uses and Advantages

- Request a Custom Quote

Still have questions? Use our live chat or contact our team for expert support on selecting, customizing, and ordering the ideal 30 gallon barrel for your application.

Invest in the right container—and streamline your storage, transport, and compliance with proven 30 gallon barrel solutions.

55 Gallon Drums

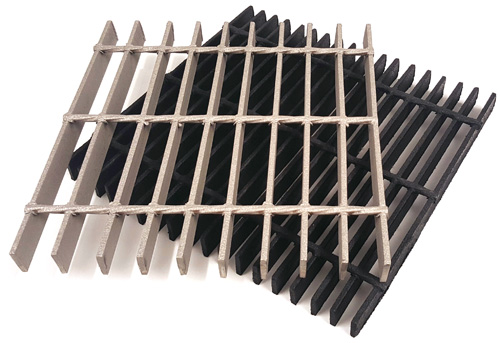

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services